Introduction

The world of design and engineering is a complex one, and the smallest parts usually have the biggest responsibility. Of these, the hinge is a wonder of silent service, a central figure in the drama of access and security that plays out every day. However, the selection of the hinge is a decision that goes much beyond mere mechanics. It is a decision of life span, beauty and the silent dialogue between a material and its surroundings. There are two materials that prevail in modern applications, namely aluminium and stainless steel. Both are champions in their own right, but their strengths are suited to different arenas.

This guide is not a simple comparison, but a profound investigation into the very nature of these materials, and one that is aimed at giving you the knowledge to make a decision not only correct, but the best possible.

What are Aluminium Hinges?

Aluminium hinges are parts made of aluminium alloys- metals that are highly valued due to their amazing lightweight and natural corrosion resistance. The third most abundant element in the Earth’s crust is the material itself, but its modern use is a tribute to metallurgical ingenuity.

An aluminium hinge is not a lump of metal; it is the result of extrusion or casting, which makes the alloy into exact, useful shapes. It is characterised by its strength-to-weight ratio. It provides a great deal of capability without the weight of too much mass, and it is a key to modern design where efficiency and streamlining are the most important factors. Moreover, aluminium has a natural passive defence mechanism of forming an oxide layer when exposed to the air, which protects it against rust and corrosion, which can be greatly increased by finishing techniques such as anodising.

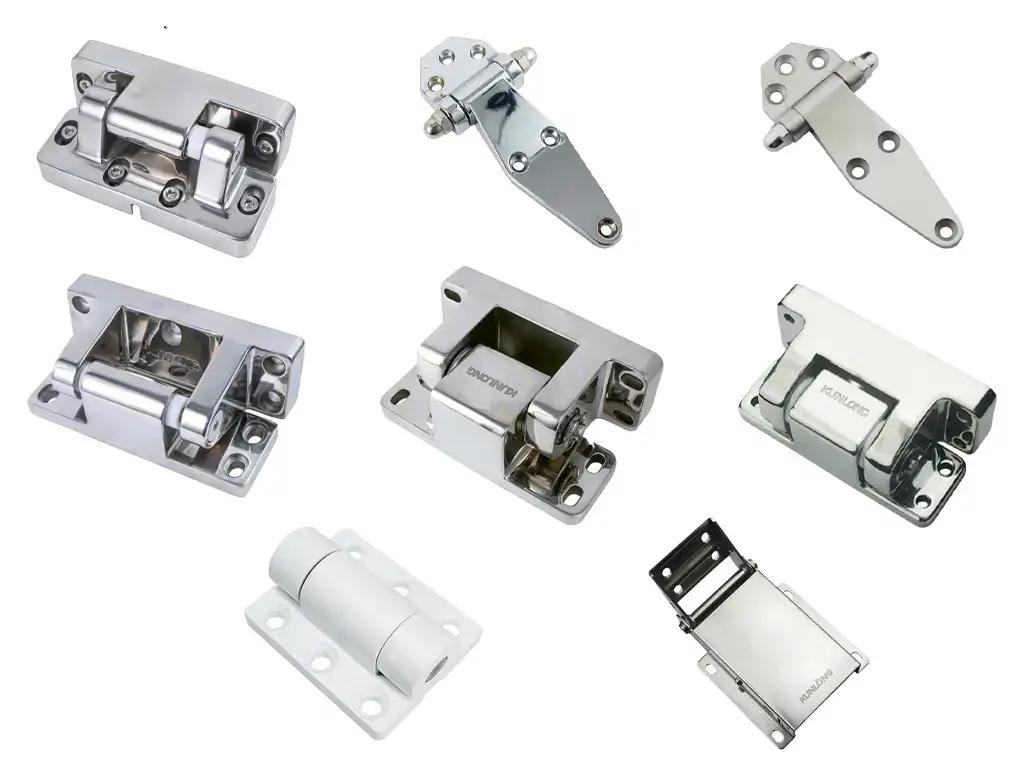

What are Stainless Steel Hinges

Stainless steel hinges are symbols of strength and resilience. They are made of steel alloys with a minimum of 10.5 per cent chromium, an element that essentially changes the interaction of the material with its surroundings. The chromium creates an invisible, passive film of chromium oxide on the surface, which is a formidable barrier to corrosion and staining–hence the name stainless. This film is unlike the oxide layer of aluminium in that it can self-heal in case it is scratched. This renders stainless steel extremely strong, especially where it is required to perform with uncompromising reliability over many decades.

They come in a range of grades, the most common being 304 (general purpose) and 316 (with molybdenum added to give better resistance in severe, chloride-containing environments such as coastal areas). A stainless steel hinge is a declaration of permanence, and is selected when strength and durability cannot be compromised.

Aluminium Hinges vs. Stainless Steel Hinges: Key Differences

Although the two materials are used to achieve the same basic purpose, their natural characteristics cause a sharp contrast in performance, use, and worth. These are some of the important differences that you should understand to match the appropriate material with the demands of your project. It is not a question of good or bad, but of suitability.

| Comparison Criteria | Aluminium Hinges | Stainless Steel Hinges |

| Weight (Density) | ~2.7 g/cm³ (≈ 2,700 kg/m³), about 1/3 the weight of stainless steel; lightweight, easier for transport and installation | ~7.9 g/cm³ (≈ 7,900 kg/m³), heavier, suitable for high-load structures |

| Yield Strength | ~55–400 MPa | ~200–500 MPa |

| Tensile Strength | ~90–550 MPa | ~500–750 MPa |

| Load Capacity (per hinge) | ~15–50 kg | Up to 100–300+ kg |

| Corrosion Resistance (Salt Spray TestASTM B117) | Anodized aluminium: ~500–1,000 hrs (suitable for general outdoor use) | 304 stainless steel: ≥1,000 hrs; 316 stainless steel: ≥2,000 hrs (suitable for high-salinity or chemical environments) |

| Appearance & Finish | Can be powder-coated in multiple colors; anodizing provides various metallic tones | Common brushed or mirror finish; fewer color options but classic look |

| Fire Resistance | Low melting point (~660°C), not suitable for fire-rated doors | High melting point (~1,400°C), can obtain fire rating (UL, etc.) |

| Thermal / Electrical Conductivity | High thermal conductivity (~205 W/m·K), good electrical conductivity | Low thermal conductivity (~16 W/m·K), poor electrical conductivity |

| Cost | $ (low unit cost, budget-friendly projects) | $$$ (high unit cost, but long service life in harsh environments) |

| Typical Applications | Lightweight doors/windows, equipment enclosures, mobile units | Heavy industrial doors, coastal buildings, chemical equipment, high-traffic areas |

Note: Values shown are typical ranges for common aluminium and stainless steel grades; actual performance may vary by alloy, finish, and manufacturer. Salt spray hours are indicative only.

Weight

The most obvious and spectacular contrast between the two materials is their density. Aluminium is very light and weighs about a third of stainless steel. This is no small difference. This mass savings is a major engineering benefit in applications where weight is a major consideration, including aerospace, transportation, or large, movable architectural components. It reduces the weight on the frame and structure, lowers shipping costs and makes the installation process easier. A technician can deal and fit a big aluminium door hinge with a comfort that would not be possible with its stainless steel equivalent.

Strength and Load Capacity

In this case, the situation is the opposite. Stainless steel has better inherent strength and stiffness. It has a greater density and a stronger molecular structure, which enables it to withstand more stress and carry much heavier loads. This disparity is measured by stringent industry standards, mostly load testing to establish maximum weight capacity and cycle-life testing to establish performance after tens of thousands of movements. This qualifies it as the unquestioned leader in heavy-duty applications: large industrial gates, solid-core commercial doors, bank vaults, and any access point where security and structural integrity are of utmost importance.

This does not imply that aluminium is weak. Contemporary extruded aluminium alloys are extremely strong, more than adequate for the needs of most standard residential and commercial doors and windows. The important difference is in the extremes. In situations where there is extraordinary weight or where high physical impact is possible, stainless steel offers a safety and performance margin that aluminium cannot, and this is frequently confirmed by a certified load rating.

Corrosion Resistance and Durability

Both materials are hailed as being corrosion resistant; however they do so in different manners and perform well in different environments.

Aluminium has a natural oxide coating. This renders it rust-proof in nature and applicable in numerous outdoor uses. Nevertheless, this layer is susceptible to strong chemicals or in very salty conditions. Surface treatments such as anodizing, which forms a far thicker, harder and more durable oxide layer, or powder coating, which encloses the metal in a protective layer of polymer, unlock the true potential of the material.

The gold standard of corrosion resistance is stainless steel, especially Grade 316. Its excellence is confirmed by standard tests such as the salt spray test (e.g., ASTM B117) in which parts are exposed to hundreds of hours of corrosive mist to replicate years of severe exposure. Its self-healing chromium oxide film is extremely tough and is virtually rust-proof and highly resistant to the corrosive action of salt spray, de-icing salts and acidic industrial pollutants. In marine work, coastal construction, or chemical processing plants, 316 stainless steel is not only the best option, it is frequently the only option. Its durability is a function of its very composition, a built-in defense that lasts the lifetime of the hinge, unaffected by a maximum storage duration before installation.

Aesthetics, Finishes, and Design Flexibility

Hinge is not just a functional part, but it is also a design element. Aluminium is more aesthetically flexible. It can be powder coated in an almost unlimited range of colors, so it can be made to match or contrast sharply with the frame it is in. Anodizing provides a variety of metallic finishes, clear matte to deep bronze and black, which adds to the natural shine of the metal, and increases durability. This is what makes aluminium a preference of architects and designers who want a unified, contemporary and minimalistic appearance, often for aesthetic and marketing purposes.

Stainless steel is more industrial and classic in appearance. It has a brushed satin or a polished mirror finish as its standard. Although it does not have the color variety of aluminium, its clean metallic look conveys a message of quality, permanence and elegant strength. It is a finish that is not trendy but establishes a classic standard of its own.

Fire Rating and Conductivity

Specialized properties are not optional in some commercial and industrial applications, but are required by safety codes. A very important example is Fire Rating. Stainless steel hinges may be fire-rated and usually have a UL listing or equivalent, which ensures that they will retain their structural integrity during a fire, even up to 20 minutes, 90 minutes, or even 3 hours, so that a door will not collapse and thereby spread fire and smoke. Aluminium, which has a much lower melting point, is incapable of attaining a fire rating and thus cannot be used in fire-rated door assemblies.

In terms of conductivity, aluminium is a very good conductor of heat and electricity, whereas stainless steel is a poor conductor. This is seldom a determining factor in the majority of hinge applications, but in special industrial or scientific equipment, it may be a factor.

Cost Analysis

Aluminium hinges tend to be cheaper than stainless steel ones on a direct, per-unit basis. The raw material is more available and extrusion and machining processes are very efficient. This cost saving can be a major consideration in large-scale projects with a strict budget.

But a real cost analysis should not be limited to the first cost. Here, the Total Cost of Ownership (TCO) comes in handy. In a typical indoor use, an aluminium hinge can provide the most cost effective value throughout its life. However, in the case of a gate on a seaside property, the initial cost of a 316 stainless steel hinge is well worth the significantly longer life and the elimination of costs and labour in the future to replace it. The hinge that you need to replace is usually the most expensive.

When to Choose Aluminium Hinges Or Stainless Steel

Knowing the specific material characteristics well, the decision process is a rational process of matching the component to its mission. The next set of criteria, which are application and performance-oriented, will lead you to the best option.

You should choose Aluminium Hinges if:

- Reduction of Weight is Essential: The application is in aerospace, mobile equipment or large panels where low mass is a key engineering requirement. This involves such parts as telecommunication enclosures, mobile medical carts and protective guarding of automated machinery.

- Complex Profiles or Heat Dissipation Required: Its extrusion suitability enables it to be used in complex custom shapes and its high thermal conductivity is an advantage in applications such as electrical cabinets and electronic enclosures where passive cooling is desirable.

- The Structural Load is Standard: In a broad spectrum of commercial and industrial doors, panels and frames where the extreme strength of steel is not necessary, aluminium offers a dependable and effective answer.

You should choose Stainless Steel Hinges if:

- Heavy Loads and Extreme Strength are anticipated: The application is oversized industrial gates, solid-core security doors, or heavy access doors on machinery that require the highest structural integrity.

- Excellent Corrosion and Chemical Resistance is Non-Negotiable: This is the absolute solution to food processing equipment, marine environments, chemical plants and any application that requires frequent and harsh wash-downs.

- Certified Fire Rating is a Legal or Safety Requirement: In fire-rated safety cabinets, building fire doors, and any compartment where fire containment is a necessity, stainless steel is required.

- The Application is Subjected to Extreme Traffic and Wear: In high traffic areas of public or industrial passageways, the high hardness and durability of stainless steel guarantee a much longer service life under continuous mechanical loads.

Solving Your Hinge Needs: The KUNLONG Approach

Understanding materials is critical, but transforming that knowledge into a reliable industrial component is what defines a true manufacturing partner. At KUNLONG, we leverage two decades of experience to do exactly that. We don’t simply supply hinges; we engineer solutions built to perform in the most demanding contexts.

- Custom Needs (OEM/ODM): When standard parts won’t suffice, our OEM/ODM expertise delivers. With a portfolio of over 700 unique functional customizations, we tailor everything from function and material to logos and finishes, offering 30+ color options. Our agile engineering team provides 3D CAD design sketches in just 7 days, turning your concept into a precision solution.

- Assured Material Reliability: Performance begins with superior materials. We exclusively use high-grade stainless steel and aluminium, fully certified by SGS and RoHS, ensuring a foundation of uncompromising quality and compliance from the very start.

- Rigorous Quality Control (QC): Our ISO, CE, and RoHS certified quality system is rigorous. Every batch undergoes 15 inspection stages, guaranteeing 100% quality assurance with precision tolerances of 0.0005mm. This process proves our hinges can withstand over 1000 hours in salt spray tests and handle extreme industrial loads, backed by a 20,000+ cycle-life guarantee.

- Expert Support: Partner with our team of 30 dedicated engineers, who bring an average of 10 years of experience to your project. We provide consultative guidance to find your optimal solution and guarantee a response to any email inquiry within 12 hours, ensuring you receive consistent, expert support.

Whether your project demands the lightweight versatility of aluminium or the rugged durability of stainless steel, our engineering team is ready to provide the optimal solution. Contact us today to discuss your specifications or to request a quote.

Installation and Maintenance Tips

Even the best hinge will perform poorly unless it is installed and maintained properly.

For Installation:

- Fasteners are Key: Never use fasteners of a different material than the one used to avoid galvanic corrosion. Stainless steel hinges should be fastened with stainless steel screws and, preferably, stainless steel or specially coated screws should be used with aluminium hinges, particularly in outdoor applications.

- Ensure Alignment: It is important that the hinge leaves on the door and the frame are properly aligned. The main cause of premature wear and binding is misalignment.

- Respect the Load: Take the right number of hinges depending on the weight and height of the door. The general rule with heavy doors is one hinge to 30 inches in height.

For Maintenance:

- Cleaning: Hinges should be wiped down occasionally with a soft, damp cloth. In stainless steel, this cleans off surface deposits that may hold moisture and corrode the passive layer. In the case of powder-coated aluminium, it maintains the finish.

- Avoid Abrasive Cleaners: Harsh chemicals, such as abrasive cleaners, steel wool, and chlorine-based cleaners, should be avoided because they can destroy the surface finish and reduce corrosion resistance.

- Lubrication: Although most modern hinges are low-maintenance, a little of an appropriate lubricant (such as a silicone spray or white lithium grease) on the pivot point once a year can keep them running smoothly and quietly.

Final Thoughts

The decision to use an aluminium hinge or a stainless steel hinge is in effect a decision about intent. It involves seeing beyond the object itself to the context in which it will be placed, the pressures it will be subjected to and the aesthetic statement it will make. Aluminium is the material of modern efficiency, light, versatile and adaptable. Stainless steel is the metal of lasting power–determined, tough, and unflinching. No one choice is best. The final manual is the application itself. With this knowledge of the unique nature of each material, you can choose not only a hinge, but the correct and permanent solution for your project. For a deeper dive into industrial hinges, visit https://www.kunlonghardware.com/industrial-hinges-guide/.