Comprehensive Quality Control

At Kunlong, quality is at the core of everything we do. Adhering to the ISO9001 quality management system and our rigorous internal controls, we ensure that every hardware component meets the highest industry standards. Our comprehensive testing process includes 15 critical evaluations, guaranteeing precision, durability, and reliability in every product.

- Home

- Comprehensive Quality Control

Performance & Quality Compliance

0

%

Accuracy Guaranteed

0

%

Critical Tests Passed

0

Years of Industry Expertise

0

Our Rigorous Testing Process

We take quality control seriously at every stage of production. Follow us to learn how every stage of our in-house manufacturing ensures 100% quality compliance.

Raw Materials Inspection

Our dedicated quality control team conducts rigorous incoming material inspections, using random sampling to assess product conformity. Only raw materials that meet our strict standards and ensure consistency are approved for production.

In-process Testing

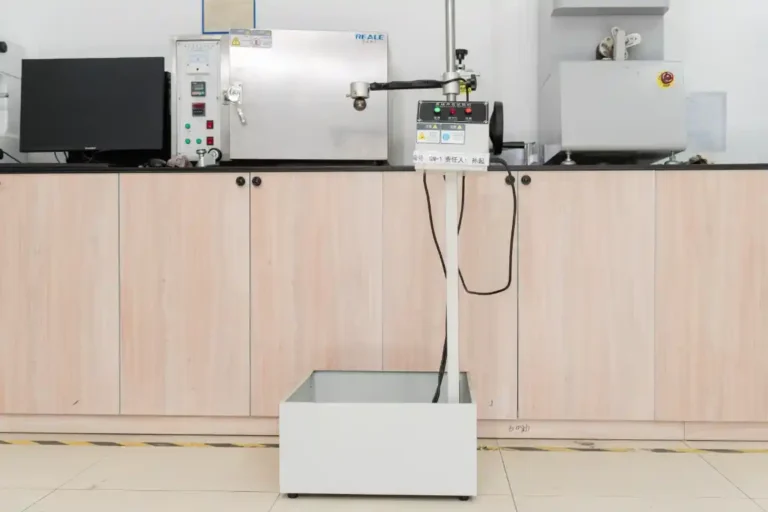

We conduct real-time inspections throughout production, utilizing advanced monitoring and testing equipment to detect and correct any potential deviations, ensuring each component meets precise specifications before advancing to the next stage.

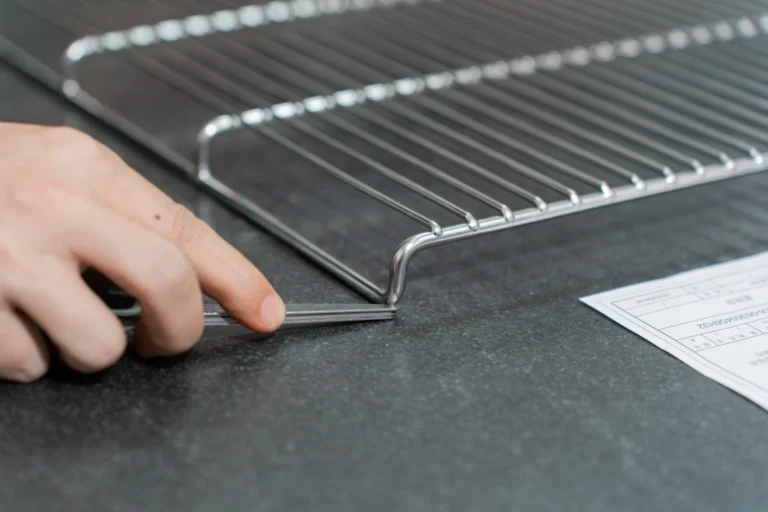

Finished Product Testing

We perform 15 essential tests on all finished products, including:

Choose KUNLONG – Proven Quality You Can Trust

Our dedication to quality has earned us the trust of customers from all walks of life, and we play a vital structural connection role in a variety of key equipment.

"Kunlong's products always exceed our expectations. The quality is reliable, the precision is unparalleled, and they match our equipment perfectly. We have chosen their hardware in multiple projects!"

"We have cooperated with Kunlong for many years, and their quality and performance are trustworthy. Most importantly, they can help us realize complex structural requirements."

“We have cooperated with Kunlong for many years, and their quality and performance are trustworthy. Most importantly, they can help us realize complex structural requirements.”

Joseph L.Mabie

“Kunlong’s products always exceed our expectations. The quality is reliable, the precision is unparalleled, and they match our equipment perfectly. We have chosen their hardware in multiple projects!”