- Home

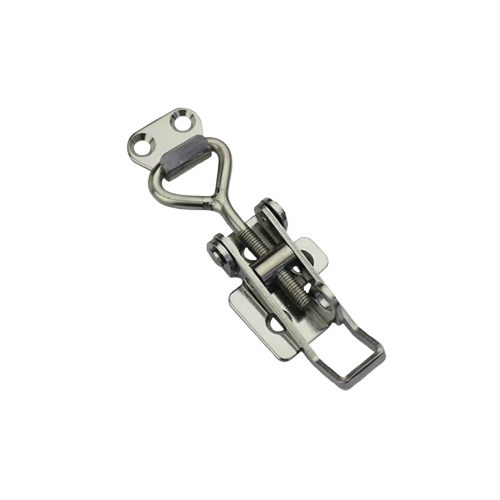

- Draw Latches

Kunlong Standard: Quality and Innovation at the Core of Every Draw Latch

Kunlong’s draw latches provide robust, vibration-resistant fastening for industrial equipment. Designed for durability and ease of use, our latches ensure tight sealing, enhanced security, and long-term performance in demanding environments. Whether for cabinets, enclosures, or machinery, Kunlong draw latches offer precision engineering for reliable operation.

Industrial-Grade Strength: Latching with Confidence

In industrial environments, a latch does more than secure a panel. It maintains structural integrity, minimizes vibration impact, and ensures operational stability. Kunlong’s draw latches are designed with high-strength materials, precision locking mechanisms, and corrosion-resistant finishes to withstand heavy-duty applications in transportation, energy, medical, and machinery industries. With a commitment to quality and customization, we provide fastening solutions that enhance both safety and efficiency in industrial settings.

Sealing and Security: The Core Advantages of Our Latches

99.8% Defect-free Rate

We guarantee that all internally produced hardware, whether hinges, handles or draw latches, has a defect-free rate of 99.8%, and any unqualified products are not allowed to leave the factory. High quality standards mean fewer returns and exchanges, thereby reducing maintenance costs for our customers.

99.99995% Processing Accuracy

Our advanced technology ensures 99.99995% machining accuracy for hardware, exceeding industry standards. An error of less than 0.0005mm allows for a perfect fit with your device and equipment, improves assembly efficiency, and helps with smooth and stable use later.

100% Quality Inspection for Every Unit

Each product undergoes a 100% comprehensive quality inspection before shipment. We have 15 inspection items, such as constant temperature and humidity test, torque test, hardness test, load-bearing test, to ensure the consistency of hardware and that there will be no defects before it reaches the hands of customers.

24,000 Times of Service Life

Our hardware is designed to withstand up to 24,000 cycles, ensuring long-lasting durability in harsh industrial environments. Longer service life means our customers can replace parts less frequently, ensuring continued trouble-free operation of their equipment while reducing maintenance costs.

Every Step Counts: Kunlong’s Production and Quality Assurance Process

Strict Selection of Raw Materials

Hinges, handles, couplings and other hardware are mainly made of stainless steel, zinc alloy, aluminum alloy, rubber, silicone and plastic. To ensure that the materials we purchase have excellent performance and meet our production standards, we have established a strict incoming material testing system and have a dedicated QC team responsible for spot checking all incoming materials.

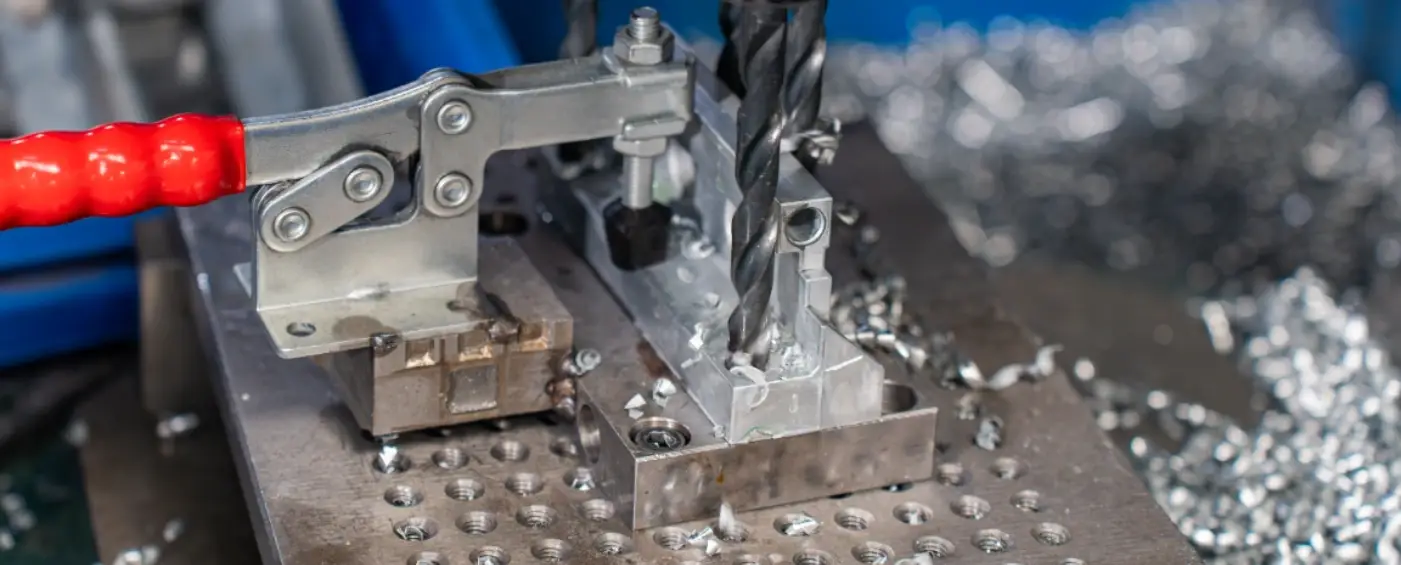

Uncompromising Production Quality

Alongside the stamping, die-casting, polishing and surface treatment to final assembly, the production of hardware also covers over 30 meticulous processes. Execution of strict control over each step guarantees accuracy and consistency. With a strong production capacity, we can meet customers’ customized needs accurately for the size, thickness, and surface treatment of the hardware.

No Defect Left Undetected

After each piece of hardware is completed, our QC team will conduct a quality inspection. Each of our tests is higher than the industry standard, which is one of the reasons why our hardware has been running stably in customer systems for a long time.

Our must-test items include:

- Temperature and Humidity Test

- UV Aging Test

- Lifetime Test

- Load Testing

- Color Difference Test

- Imaging Test

- Height Measurement Test

- Low Temperature Test

- Alcohol Abrasion Resistance Test

- Torque Test

- Coating Test

- Hardness Test

- Salt Spray Test

- Impact Test

- High Temperature Test

24,000 Uses Warranty Coverage

We offer comprehensive warranty coverage for all our hardware products, including hinges, locks, handles, couplings, and more. Prioritizing your user experience, we ensure prompt warranty responses (replacement or repair) for hardware with up to 24,000 cycles of use, minimizing any impact on your operations.

Only Hardware that Meets Our Strict Quality Standards Is Accepted, Produced, and Delivered.

Ready to Improve Your Hardware Performance with Our Industry-Specific Solutions?

1. Can I get a sample of the cam lock before placing a bulk order?

Of course, we provide samples for your testing.

2. What is the lead time for customized or mass production orders?

Standard products are shipped within 7 days, and customized products are according to specific solutions, generally within 30 days.

3. Do you provide certifications for product compliance and safety?

We have complete certificates, including CE, SGS, ISO, ROSH, REACH and other certifications.

4. Do you offer after-sales support and warranty for your products?

We provide at least 1 year of after-sales service and make regular visits to ensure the continued stability of the product.