Electromagnetic interference is a widespread and growing problem in contemporary engineering. The crowding of electronic equipment, both in consumer goods and in vital military systems, creates a complicated electromagnetic field environment. These fields, when not controlled, can destroy or impair the operation of sensitive electronics. The basic practice of isolating devices against this electromagnetic pollution is called EMI shielding. This reading will describe the concepts of electromagnetic shielding, the materials involved, including magnetic materials, the importance of mechanical design, and the integration best practices. It is a roadmap to the realization of shielding as not only a material property but as a system.

What is EMI Shielding & Why it Matters?

Electromagnetic Interference (EMI) is an undesired perturbation produced by some external source that interacts with an electrical circuit by electromagnetic induction, electrostatic coupling, or conduction, including issues such as radio interference. It is, in short, electronic noise. The origins of this interference are diverse and may be classified as man-made or natural.

Artificial sources are everywhere and can be anything, as small as power lines and radio frequency transmitters or as large as the internal parts of an adjacent electronic device. Any electrical circuit may be a source of unwanted electromagnetic energy, as well as a victim of it. The electromagnetic environment has become much denser with the proliferation of high-speed digital circuits, wireless communication systems, and switching power supplies.

Natural phenomena, such as solar flares and lightning strikes, are considered natural sources and can cause strong electromagnetic pulses that can damage or interfere with unprotected electronics over a wide radius.

EMI shielding plays a direct and critical role in ensuring that electromagnetic energy does not disrupt the operation of electronic devices. It is a reduction practice that reduces the electromagnetic field to a point where it will no longer be a source of performance problems. The application of this practice cuts across almost all the areas where electronics are applied.

Consider these application scenarios:

- Medical Devices: A pacemaker or an MRI machine should work with 100 percent reliability in a hospital setting. Without adequate EMI protection, the operation of their device could be disrupted by stray electromagnetic radiation emitted by a nearby cell phone or other electrical devices, which would pose a life-threatening scenario.

- Aerospace and Defense: Military aircraft and aerospace avionics must work in a high-radar and communication-intensive environment. Shielding is required to ensure that sensitive electronics are not disrupted, and mission-critical systems will continue to operate. This is national security and the safety of personnel.

- Automotive: Modern cars are sophisticated electronic devices with dozens of microprocessors that manage the timing of the engine, as well as sophisticated driver-assistance systems. Shielding is used to keep the high-power components of the vehicle, such as ignition systems or electric drive motors, out of the sensitive control and navigation electronics of the vehicle.

The lack of effective EMI shielding would essentially undermine the reliability of electronic devices that form the basis of modern infrastructure.

How EMI Shielding Works

The role of an EMI shield is to form a barrier that impedes the path of electromagnetic waves, including radio waves. This is achieved by two main physical processes, namely reflection and absorption. The enclosure that does this work is commonly known as a Faraday cage, an enclosure that is used to shield electromagnetic fields.

When an electromagnetic wave interacts with a conductive material, the interaction is defined by the properties of the material and the wave.

1. Reflection: Reflection is the first and most important shielding mechanism at most frequencies. The shield material should be highly electrically conductive. Upon impact of the electromagnetic wave on the surface of the shield, the charge carriers of the conductive material (electrons in a metal, say) are excited to vibrate. This vibration generates a second electromagnetic field, which is in opposition to the incident field. The energy of the incoming wave is reflected, in large part, by the surface of the shield, which cannot be penetrated. The more conductive the material, the better the reflection.

2. Absorption: The electromagnetic energy that is not reflected and enters the shield material is then absorbed. The wave causes currents as it travels through the conductive medium. These currents produce heat, transforming the electromagnetic energy into thermal energy because of the resistance of the material. This dampens the wave as it goes through the shield thickness. The absorption performance is determined by the thickness of the shield and its magnetic permeability. To provide shielding against low-frequency magnetic fields, high-magnetic-permeability materials are needed to absorb the energy of the field.

A good EMI shield is thus an application of a Faraday cage surrounding sensitive electronics. This electromagnetic shielding barrier reflects most of the incident electromagnetic radiation at its outer surface and absorbs much of the remaining energy that penetrates the material, preventing the internal electrical circuits of the material from being disrupted.

Key Materials for Effective EMI Shielding

The choice of shielding material depends on the application needs, such as the frequency range of the interference, the environment, the mechanical properties, and cost. There is a large selection of conductive materials.

- Solid Metals: Metal sheets are a conventional and very efficient solution. Copper, aluminum, and stainless steel are metals that are highly electrically conductive and can be very effective shields over a wide frequency range. Copper is commonly regarded as the performance standard because it is more conductive than aluminum, which is lightweight and less expensive. Stainless steel is durable and resistant to corrosion.

- Conductive Coatings: In applications where the enclosure is composed of a non-conductive material such as plastic, conductive coatings are used. These finishes are filled with conductive fillers like nickel, copper, silver, or carbon nanotubes suspended in a binder. They may be sprayed or brushed on, forming a conductive coating on the inside walls of the enclosure.

- Conductive Gaskets and Elastomers: EMI shielding gaskets are needed to seal the seams and joints of an enclosure. They are normally composed of an elastomeric substance, such as silicone, stuffed with conductive particles. These gaskets are installed between mating surfaces, e.g., a door and its frame, to provide a continuous conductive path and eliminate leakage.

- Metal Foils and Tapes: Tapes are adhesive-backed copper or aluminum foils that are used to seal smaller gaps, wrap cables, or shield particular components of a larger system. They provide a simple and easy application.

- Wire Mesh: Woven or expanded metal mesh may be utilized in applications where ventilation or visual transparency is required, e.g., shielded windows. The upper-frequency limit of the shielding effectiveness of the mesh is determined by the size of the openings in the mesh.

Below is a comparative table of common shielding materials:

| Material Type | Advantages | Disadvantages | Applicable Frequencies | Relative Cost |

| Solid Copper/Aluminum | High conductivity, excellent SE | Heavier, can be costly, requires fabrication | Broad (Low kHz to >10 GHz) | Moderate to High |

| Stainless Steel | Durable, corrosion-resistant | Lower conductivity than Cu/Al | Broad (Low kHz to >10 GHz) | Moderate |

| Conductive Coatings | Lightweight, conforms to complex shapes | Susceptible to scratching, lower SE than solid metal | Mid to High (>10 MHz) | Low to Moderate |

| EMI Gaskets | Seals gaps, provides environmental sealing | Requires specific compression, can wear over time | Broad, depends on filler | Moderate |

| Metal Foil Tapes | Flexible, easy to apply for spot shielding | Lower durability, adhesive can degrade | Broad, depends on adhesive conductivity | Low |

| Wire Mesh | Allows airflow/visibility | Limited SE at higher frequencies | Mid to High (>1 MHz) | Moderate |

The choice of material is the first step in a successful shielding strategy. However, material selection alone is insufficient.

Beyond Materials: The Critical Role of Enclosure Integrity

Theoretical shielding effectiveness of a particular material can be of little importance in practice when the mechanical integrity of the enclosure is lost. An EMI shield is a system. It is not its strongest element that defines its performance, but its weakest. The physical discontinuities in the enclosure are the most likely source of failure in an EMI shielding design, rather than the material.

Any seam, joint, slot, or hole in a shielded enclosure is an aperture. Electromagnetically, these apertures are slot antennas. As the physical length of an aperture becomes a large fraction of the wavelength of the incident electromagnetic wave, the aperture will permit the passage of that wave with minimal attenuation. A long, narrow hole may be a much greater leak than a round hole of equal surface area.

This implies that even an enclosure made of thick, solid copper will be a poor shielding device unless its door fits perfectly against the frame. The narrow, persistent discontinuity between the frame and the door forms a long slot antenna that is able to couple electromagnetic energy in and out of the enclosure. Likewise, the integrity of the Faraday cage is compromised by unsealed seams between panels, unfiltered cable access points, and ventilation holes.

Good enclosure design aims to remove or reduce these apertures. The overlapping of the seams should be secured by means of fastening or, more often, by means of conductive EMI gaskets. Any openings that are required should be handled in a special way to minimize the possibility of leaking. It should be assumed that any discontinuity in the conductive continuity of the enclosure is a possible failure point.

Selecting Critical Hardware for Shielded Doors and Panels

Since enclosure integrity is the most important factor, the industrial hardware employed in the construction and securing of the enclosure is not a secondary factor; it is a key element of the shielding system. The locks, latches, and hinges that hold doors and access panels closed are directly involved in ensuring the continuous, low-impedance seal that is needed to ensure effective shielding.

- Latches and Locks: The main purpose of a latch or lock in a shielding application is to exert a consistent and adequate compressive force on the EMI gaskets that line the door or panel frame. To properly deform and form an effective conductive seal between the mating metal surfaces, the gasket must have a certain amount of pressure. When the force is not sufficient, there will be gaps, and the seal will not be complete. When the force is excessive or not evenly distributed, the gasket may be permanently damaged, which affects its long-term performance. Good latches, especially with adjustable compression, enable the designer to adjust and hold the correct force needed to achieve the best gasket performance on the entire perimeter of the opening.

- Hinges: Hinges also play an equally important role, particularly on large or heavy shielded doors, which are typical of equipment racks or environmental test chambers. An improperly designed or undersized hinge will cause a heavy door to hang under its own weight with time. The result of this sagging is a tapered gap at the top and side of the door opposite the hinge that breaks the seal and provides a large EMI leakage path. High-precision, heavy-duty hinges are necessary to hold the door’s weight without bending throughout its entire lifecycle, and to maintain the seal’s alignment and integrity intact after thousands of opening and closing cycles.

In this regard, collaboration with a special hardware producer is a very important design consideration. KUNLONG has more than 20 years of experience in engineering and production of industrial hardware to be used in challenging applications. We know that a shielded enclosure does not have a latch as a closing device, and a hinge as a pivot. They are developing parts that are critical to the performance of the system. Our products are produced using superior quality materials such as SUS304 and SUS316 stainless steel to make them durable and resistant to corrosion, and they are subjected to tens of thousands of cycles to ensure reliability over time. To the engineer who is designing a shielded system, the choice of hardened, proven hardware is a direct investment in the performance and the life of the end product.

EMI Shielding Challenges Across Key Industries

Although the principles of shielding are universal, the challenges and design priorities are quite different across industries.

- Aerospace and Defense: This industry requires the utmost reliability in harsh environmental conditions. The shielding should be resistant to high-power radar, communications systems, and possible electronic warfare threats. Components should be of high military quality (e.g., MIL-STD-461) and should be able to endure extreme vibration, shock, and temperature. Cost is second to redundancy and absolute performance.

- Medical and Healthcare: The first issue is patient safety and the accuracy of diagnosis. Shielding helps to keep medical equipment such as patient monitors and infusion pumps unaffected by the multitude of RF sources present in a hospital. In the case of sensitive diagnostic equipment such as MRI and EEG machines, shielding is necessary to ensure that external noise does not corrupt the low-level signals to give wrong diagnoses.

- Telecommunications and Data Centers: The problem in this industry is the handling of very high concentrations of electronic equipment. In the case of 5G communication cabinets and data center racks, shielding is required to avoid crosstalk and interference between adjacent systems. The major problem is striking a balance between shielding and thermal considerations; cooling needs to be well ventilated, but all vents are potential EMI leakages and should be designed carefully.

- Automotive and E-Mobility: The contemporary vehicle, especially an electric vehicle (EV), is an electromagnetically complex space. Powerful electric motors, high-voltage batteries, and inverters produce a lot of EMI. This noise should be enclosed so as not to interfere with critical control systems, GPS navigation, and infotainment systems. Shielding solutions should be light, economical, and capable of surviving the extreme automotive environment.

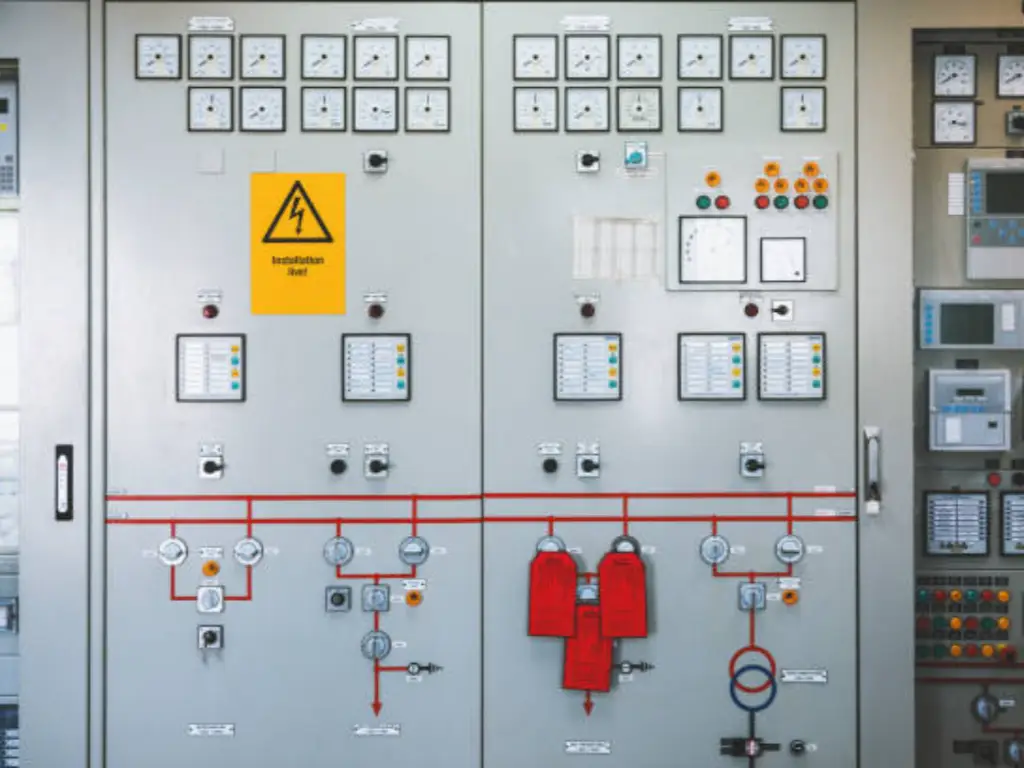

These general applications are subdivided into more specialized applications in which the mechanical hardware has an even more significant role. Take into account environmental test chambers in production and research. These chambers should offer a shielded environment and expose a device to extreme temperatures, between -70 °C and more than 200 °C. The hardware, such as hinges and latches, should not just be a perfect EMI seal, but should also be able to work reliably under these extreme thermal conditions without breaking or causing the door to distort. Likewise, the large industrial control cabinets on a factory floor should shield delicate electronics against the strong EMI emitted by the nearby motors and machinery, and their heavy doors should be perfectly aligned over the years of repeated use. In such applications, the choice of proven, high-durability hardware is central to the operation of the equipment.

Best Practices for Shielding Design and Integration

EMI shielding is not an option; it is a fundamental design science that should be addressed at the earliest product design phases. It is always more costly and less efficient to retrofit an already designed shielding than to incorporate these principles during design. This section is a detailed guide to the best practices of design, integration, and verification.

1. Basic Enclosure Design

The shielding system is based on the physical enclosure. It should be designed in such a way that it is electromagnetically contained.

- Material Selection: As explained above, the first consideration is the material (electrical conductivity and magnetic permeability). This choice has to be made at the initial stage because it affects mechanical design, weight, cost, and thermal properties. It should be chosen depending on the frequency that is to be shielded and the environmental factors, including the requirement of corrosion resistance.

- Wall Thickness: The thickness of the shielding material required is dependent on the attenuation mechanism. In high-frequency EMI where reflection is the dominant shielding mechanism, conductivity is more important than thickness. A thin layer of extremely conductive material can be quite efficient. But in the case of low-frequency magnetic fields, where absorption is the most important process, thickness is important. The higher the material thickness, the higher the absorption loss, and the field is attenuated on its way through.

- Aperture Discipline: The perfect shielded enclosure is a smooth, conductive box with no holes. This is not feasible, but the principle to be followed in early design must be aperture discipline: keep the number and size of all openings to a minimum. Any necessary holes in the cables, displays, buttons, or ventilation should be justified and treated. Even small, unnecessary holes in the design should be avoided at the very beginning.

2. Managing Necessary Apertures

As a fully sealed box is often not an option, one of the most important aspects of the design process is the control of the required openings so that they do not become sources of EMI leakage.

- Seams and Joints: Panels in an enclosure should be joined together to create a continuous conductive path. The most common form of aperture is the seams of these panels. The answer is conductive EMI gaskets, which are fitted to the seams and clamped by fasteners. The screw pattern, the count, and the distance between screws are important to provide a consistent force on the gasket and a low-impedance electrical connection over the full length of the seam.

- Display Screens: Displays need transparent openings, and these can be major sources of EMI leakage. Shielded windows are used to resolve this. These are generally built in either of the two forms:

- Micromesh: A fine-gauge metal mesh is laminated onto or into a glass or polycarbonate window. The mesh forms a Faraday cage effect and is sufficiently fine to be optically clear.

- Conductive Coatings: A transparent conductive coating is applied to the window surface, e.g., Indium Tin Oxide (ITO). This coating offers good shielding at radio frequencies and is grounded to the enclosure chassis.

- Ventilation Ports: Cooling airflow may be required, but vents may be large holes. Honeycomb vents are the typical answer. These are a combination of fused small and deep hexagonal tubes. This construction is a waveguide-below-cutoff. Air is free to pass through, but electromagnetic waves above the cutoff frequency of the waveguide cannot propagate through the small tubes and are reflected. This enables good ventilation with minimum loss to shielding integrity.

3. Controlling Inputs and Outputs (I/O)

The most typical route of EMI to go around a shield is through cables. The enclosure may be designed to perfection, but when a cable is used as an antenna, the system will fail.

- Cable Shield Termination: The shield of a shielded cable should be terminated with a 360-degree low-impedance connection to the wall of the enclosure at the entry point. This is done by specialized shielded connectors and backshells. The usual mistake of connecting the shield to the chassis with a “pigtail” wire should be avoided, since this forms an antenna and is not effective at high frequencies.

- Filtering: Unshielded conductors (including power lines and signal lines) that need to go through the enclosure wall should be filtered. EMI filters are placed at the entry point to remove undesirable high-frequency noise on the lines so that it is not carried into or out of the enclosure.

4. Implementing a Low-Impedance Grounding Strategy

Shielding is based on proper grounding. In the case of EMI, a ground is a low-impedance noise-current return path. The shield itself should be tied to the chassis ground of the system to give a reference point and drain induced currents. Such connections must be done using wide straps or direct surface contact rather than thin wires to reduce inductance and be effective at high frequencies.

5. Verification Through Testing

The last one is to check the performance of the design. Shielding Effectiveness (SE) is a unit of decibels (dB), which is a measure of the attenuation of an electromagnetic field by a shield. This is the only means of testing empirically that the design decisions have led to a product that fulfills its needs, including those of regulatory agencies like the Federal Communications Commission (FCC). It is done by putting the device in a controlled environment and measuring its emissions and susceptibility with antennas and spectrum analyzers over a frequency range.

Conclusion

Effective EMI shielding is not a feature that can be added to a product at the end of the design cycle. It is a system engineering field where physics, materials science, and mechanical design must be thoughtfully considered at the very beginning. An unbroken chain of decisions defines the performance of a shield: the choice of appropriate materials, the integrity of the enclosure structure, cable shielding, the quality of the hardware that keeps it together, the treatment of all apertures and cable penetrations, and an appropriate grounding strategy.

The breakdown of one of the links in this chain can make the whole system useless. Thus, it is not a luxury but a necessity to deal with suppliers who have profound knowledge in their areas of expertise. When it comes to the critical mechanical hardware that guarantees the physical integrity of your shield, it is necessary to cooperate with a professional hardware supplier. We urge you to seek the advice of experts in order to make sure that each part of your design makes a positive contribution to the overall objective: a product that works reliably in its desired electromagnetic environment.