Introduction

Heavy duty hinges are essential elements in applications where the standard hardware cannot be used to handle heavy loads and frequent use. They are designed to be strong, durable and reliable, and they are the point of contact with huge doors, industrial gates and special equipment. In contrast to their residential needs counterparts, these hinges are not just facilitators of movement, but structural supports that must be able to withstand enormous physical stress over long service lives. This guide is a thorough analysis of heavy duty hinges, including their defining features, main types, material content, and the key considerations that determine their use in particular, challenging applications, offering a comprehensive range of solutions.

What Defines a “Heavy Duty” Hinge?

The term heavy weight or “heavy duty” is not randomly assigned to a hinge. It is the outcome of certain engineering and material decisions that make it stand out among the standard-grade hardware. The main difference is that it has a load-bearing capacity, which is a direct result of its physical structure and the materials.

To begin with, the thickness of the hinge leaf material is much greater. This added thickness does not allow the metal to bend, flex or fatigue due to the high static and dynamic loads applied by a heavy door or gate. The pivot point is a pin that is much larger in diameter and is usually hardened steel to withstand shearing and wear.

Moreover, the knuckle of the hinge, the cylindrical portion in which the pin is received, is longer, and is more strongly constructed. This increased surface area aids in the distribution of the load, which minimizes stress concentration at any one point. One of the characteristics of most heavy duty hinges is the incorporation of bearings. These may be ball bearings, roller bearings or thrust bearings, between the knuckles. They serve to minimize friction when moving, which is essential to the smooth operation of a heavy door and to dramatically increase the service life of the hinge by reducing metal-on-metal wear.

Key Types of Heavy Duty Hinges

The choice of a heavy duty hinge is essentially related to the application requirements. Various designs have different mechanical benefits and it is important to know the types in order to specify them correctly.

| Hinge Type | Structural Features | Advantages | Typical Applications |

| Butt Hinges | Two equal leaves joined by a central pin, often with ball bearings | – Easy to install – Designed for high -frequency operation – Smooth swinging motion – Clean and flush appearance | – Heavy commercial door hinges – Industrial doors |

| Piano Hinges | Full-length hinge spreads load along door edge | – Uniform load distribution – Prevents door sag or warp – Increases durability | – Industrial cabinets – Tool chests – Security enclosures |

| Offset Hinges | Pivot axis offset to allow door to clear frame fully | – Maximizes opening clearance – Meets accessibility requirements – Allows passage of large equipment | – Hospital entrances – ADA-compliant doors – Industrial equipment rooms |

| Concealed Hinges | Fully hidden when the door is closed, mortised in | – High tamper resistance – No visible hardware – Sleek and modern appearance | – Architectural doors – Security doors – Armored doors |

| Strap Hinges | Long leaves provide wide mounting surface | – High load-bearing area – Resists door sagging – Great for outdoor, rustic uses | – Barn doors – Gates – Carriage doors |

| Pivot Hinges | Weight carried by floor-mounted pivots | – Extreme load capacity – No frame stress – Perfect for oversized, heavy doors | – Monumental doors – Glass panels – Vault doors |

| Weld-On Hinges | Welded directly to metal frame and door | – Permanent, ultra-strong mount – No fastener failure points – Ideal for harsh industrial use | – Shipping containers – Machinery guards – Armored enclosures |

Butt Hinges

One of the most popular types of heavy duty butt hinges is used on heavy commercial and industrial doors. They are made of two leaves of the same size and connected with a central pin. These hinges are made with thicker leaves and a larger, stronger pin to suit heavy duty applications. They are nearly always fitted with ball bearings–usually two or four to each hinge–between the knuckles. These bearings are necessary to minimize friction and enable a heavy door to swing easily with little effort. They are mortised into the door and frame, so that when the door is closed, it has a clean, flush look.

Piano Hinges

Piano hinges are also called continuous hinges and extend the entire length of the door or panel they are mounted on. Their main strength is the even weight distribution throughout the height of the connection. This design reduces the stress on any one point of the door and frame, and is suitable where the panels are very long or heavy, as in industrial cabinet doors, tool chests, and security enclosures. The piano hinge in heavy duty versions will have a larger diameter pin, thicker leaf material and a heavier knuckle design to support large loads without sagging or warping with age.

Offset Hinges

Offset hinges are special hinges that enable a door to swing out of the frame, thus maximizing the clear opening width. This is done by having the pivot point not on the mounting plane of the hinge. This feature is essential in settings where accessibility regulations are in place or where bulky equipment needs to fit through door frames. The heavy duty offset hinges are constructed with the necessary strength to bear the weight of a heavy door and still offer this special swinging action, and are therefore necessary in hospitals, manufacturing plants and in buildings open to the general public.

Concealed Hinges

Concealed hinges, sometimes called invisible hinges or Soss hinges, are mortised into the door and frame so that they are not visible at all when the door is closed. This offers a very good security since the hinge pins are not accessible and cannot be interfered with. It also provides a minimalist, clean look. Concealed hinges are designed to carry heavy doors and are manufactured with multiple pivot points made of high-strength steel alloys. Their advanced design qualifies them as the best option in architectural use, security doors and armored panels where strength and appearance are of utmost importance.

Strap Hinges

Strap hinges are hinges with long leaves, or straps, that span the face of the door and frame. This design gives a lot of surface area to mount on and this spreads the load on a larger part of the door. This renders them particularly suitable to very broad, heavy and rustic uses such as barn doors, large gates and carriage house doors. The long straps give a lot of leverage and support and the door does not sag with time. Thick-gauge steel is used to make heavy duty versions, which are frequently coated to protect against outdoor environmental conditions.

Pivot Hinges

Pivot hinges are made to accommodate the heaviest of doors by placing the pivot point at the top and bottom of the door, not the frame. The bottom pivot assembly supports the weight of the door and is not suspended on the door frame. This puts all the weight directly on the floor structure, and doors much heavier than a conventional frame-mounted hinge could support can be installed. Monumental architectural doors, large glass panels, and high-security vault doors are standardized with heavy duty pivot hinges.

Weld-On Hinges

Weld-on hinges are permanent, high-strength hinges that are welded to a metal door and a metal frame. This forms a smooth and very strong connection, which does not have the possibility of failure of fasteners. They are normally made of carbon steel or stainless steel to allow a good weld. The most demanding industrial applications, such as on shipping containers, heavy machinery guards, armored vehicles, and high-security safes, require absolute strength and permanence, and are specified with heavy duty weld-on hinges.

Choosing the Right Material for Your Environment

The durability and functionality of a heavy duty hinge rely on both the material composition and design. The main factor that determines the right material is the operational environment.

Stainless Steel

Stainless steel is a better option when it comes to applications that are subjected to moisture, humidity and corrosive elements. The most popular grades of heavy duty hinges are 304 and 316. Grade 304 is a good choice in most environments and is a standard in outdoor use, food processing plants, and medical environments. Grade 316 has molybdenum that offers a much greater degree of resistance to chlorides and other severe chemicals. This qualifies it as the necessary material in marine use, coastal regions, swimming pool enclosures and chemical plants.

Carbon Steel

Carbon steel is highly appreciated due to its high strength, hardness, and affordability. It has a greater tensile strength than most stainless steels, and is therefore a good choice where the main issue is the control of very high loads in a controlled, dry environment. Heavy duty carbon steel hinges are prone to rust and therefore need to be coated. Zinc plating, galvanization, powder coating or a primer paint are common finishes that offer a strong protection against corrosion.

Brass

Brass is a copper-zinc alloy with good corrosion resistance and a characteristic look. Solid brass heavy duty hinges are not as strong as steel but are strong enough to suit many applications and are frequently selected because of their appearance. One of the most important functional properties of brass is that it is non-sparking, which is an essential safety feature in explosive or flammable areas. It is also naturally antimicrobial, and thus it is an appropriate option in some public and healthcare uses.

Aluminum

Aluminum is valued because of its strength-to-weight ratio and inherent corrosion resistance. Although it lacks the sheer strength of steel, heavy duty aluminum hinges are perfect in situations where weight is a major factor like in the aerospace and transportation sectors. The material is a passive oxide layer that prevents corrosion, which makes it applicable outdoors. It is a practical decision in which a compromise between moderate strength, low weight, and environmental resistance is required.

How to Choose the Right Heavy Duty Hinges

The right heavy duty hinge should be chosen in a systematic manner. This entails a keen evaluation of various interdependent factors to guarantee safety, functionality and durability.

Load Capacity Assessment

This is the most important calculation. You have to calculate the weight of the door or panel. The width of the door however also affects the effective load on a hinge; a wider door has more leverage and therefore more stress on the hinges. One of the general formulas is to multiply the weight of the door by its width. The total load capacity of all hinges employed must be greater than this calculated value, by a large margin. Manufacturer specifications should always be consulted and they give clear weight ratings of their products.

Optimal Size & Dimensions

The hinge should be proportional to the size and thickness of the door. The general thumb rule is to choose a hinge height depending on the thickness of the door. As an example, a 1-3/4 inch thick door will normally need a 4.5-inch high hinge. The hinge should also be wide enough to accommodate any trim or obstructions on the frame so that the door can swing open. An undersized hinge will fail prematurely.

Usage Frequency

The expected frequency of use dictates the need for specific features. In a high-traffic entryway that is opened hundreds or thousands of times a day, high-quality ball bearing hinges are not optional, they are a requirement. A simpler pin-and-barrel hinge may be adequate in the case of a low-frequency access panel. Frequent use increases wear, and it is important to select a hinge that is rated for the desired number of cycles to prevent frequent repair and replacement.

Installation Method

The door and frame construction will dictate the installation method required. Metal doors and frames require weld-on or surface-mounted hinges and through-bolts. Mortise hinges are usually needed on wood doors, and are recessed into the wood to fit flush and hold well. The decision to use welding, machine screws or wood screws is a basic decision which affects the strength and stability of the installation in general.

Functional & Security Requirements

Take into consideration any special functional needs. Does the door have to swing out of the frame? In that case, an offset hinge is needed. Hinges with non-removable pins (NRPs) are necessary in security-sensitive areas, particularly out-swinging exterior doors. A stud on one of the leaves of an NRP fits into a hole in the other when the door is closed, so that the pin cannot be removed to remove the door from its hinges. Additionally, consider spring hinges for self-closing applications, offering convenience and control.

Aesthetic Considerations

Although form is secondary, it is also a consideration in most projects. The finish and look of the hinge are important in architectural or customer-facing applications, contributing to its unique selling proposition (USP). Hinges come in many different finishes, including polished brass and stainless steel, matte black and oil-rubbed bronze. The decision to use a visible hinge such as a strap hinge or a totally invisible concealed hinge will essentially change the overall appearance of the installation.

Top Applications of Heavy Duty Hinges Across Industries

Heavy duty hinges are essential in a very large number of industries:

- Architecture and Construction: For monumental entry doors, large gates, and high traffic commercial buildings.

- Industrial Manufacturing: On heavy machinery guards, equipment access panels, industrial ovens, machinery covers, electrical panels, storage cabinets

- Security and Defense: For vault doors, armored vehicle doors, prison gates, and secure facility entrances.

- Transportation: During the manufacture of shipping containers, trailers and doors on specialty vehicles such as fire trucks, trucks, rail cars and ambulances.

- Marine: For hatches, doors, and cabinets on ships and offshore platforms where strength and corrosion resistance are paramount.

- Aerospace: On cargo bay doors and ground support equipment where strength-to-weight ratio is important.

Essential Installation and Maintenance Tips

Proper installation is non-negotiable for performance.

Make sure that all hinges are plumb and aligned with one another. Misalignment causes the whole weight to be focused on one hinge, which causes quick failure.

Apply the right fasteners and the right amount of fasteners and tighten them to the right torque. In mortise hinges, the cutout should be accurate so that the hinge can fit flush and stable.

Maintenance, while minimal for well-chosen hinges, should not be overlooked.

Check and tighten any loose fasteners periodically.

In dusty or debris-filled environments, clean the hinges to avoid the possibility of particulates increasing wear.

In hinges that do not have sealed bearings, a regular application of a suitable lubricant (e.g., white lithium grease) may be used to maintain smooth operation and avoid corrosion of the pin.

Why Partner with a Specialist Heavy Duty Hinge Manufacturer?

While hinges may appear simple, selecting the right heavy-duty hinge is critical for safety, stability, and long-term performance. Partnering with a specialist manufacturer offers significant advantages over general hardware suppliers. Backed by deep engineering expertise in load mechanics and material science, a specialist can guide you in selecting the best hinge for complex applications, helping you avoid costly mistakes.

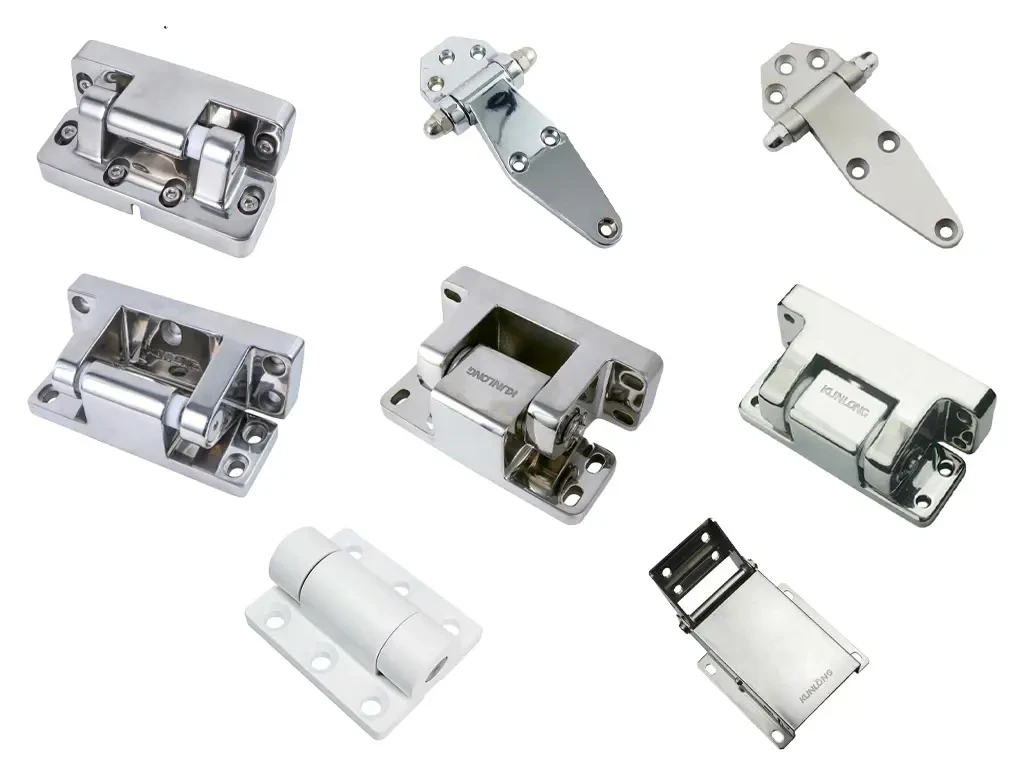

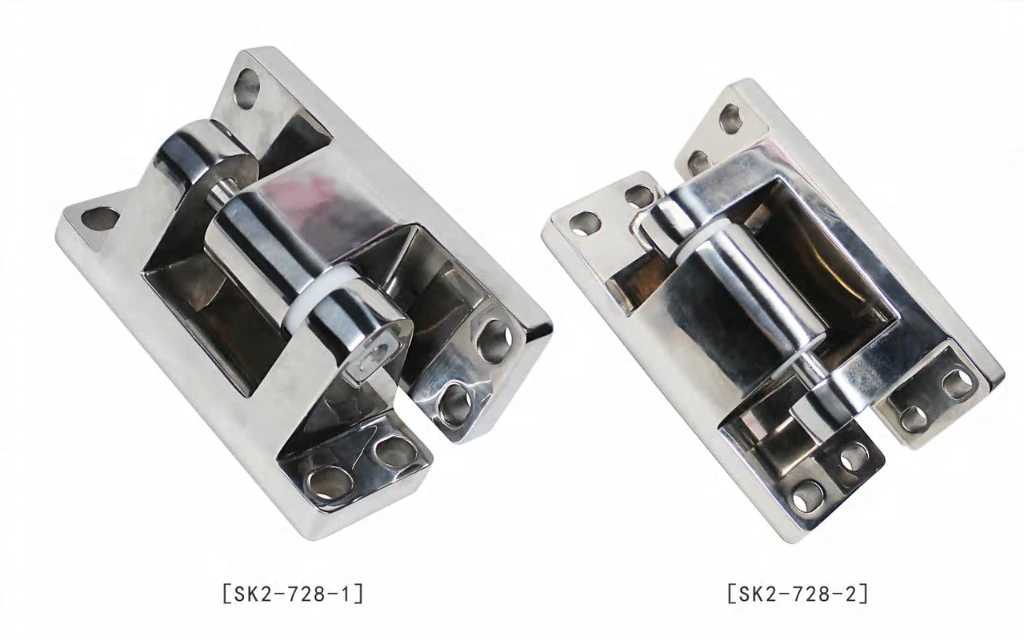

With over 20 years of industry experience, KUNLONG delivers professional industrial component solutions across 12 industries, trusted by over 20,000 customers worldwide. Our in-house R&D team, with 30 engineers averaging 10 years of experience, has supported customers in developing over 700 customized functions to meet unique application needs, including heavy-duty hinge customization when required.

KUNLONG implements strict quality control throughout the entire production process, ensuring each hinge meets load capacity, material integrity, and dimensional accuracy requirements, with tolerances controlled within 0.0005mm. All materials are SGS tested and certified for ROHS compliance, while products undergo 15 inspections per batch.

Our hinges offer high load-bearing capacity, exceptional corrosion resistance (1000h salt spray), and performance stability, with additional features such as anti-bacterial, anti-corrosion, and wide temperature tolerance, ensuring your industrial projects achieve reliable, long-term performance.

Contact us today to discuss your heavy-duty hinge needs and receive expert guidance for your projects.

Conclusion

Heavy duty hinges are manufactured parts that are used to carry out a very important task in a harsh environment. The selection of the right hinge is a technical process and it involves a careful study of the load, environment, frequency of use, and functional requirements. Whether it is the rugged simplicity of a weld-on hinge to an industrial application or the complex mechanics of a concealed hinge to an architectural door, each type has a particular solution. With the knowledge of the defining characteristics, material properties, and the selection criteria, engineers, architects, and facility managers can be assured that they select a component that will offer safety, durability, and reliable performance throughout its intended service life.