Introduction

The hinge is a basic element in the large and complex world of mechanical engineering and industrial design, a pivot point on which functionality and durability hinge. It is a part of the work of many applications, large and small, industrial and medical, architectural and artistic, that is not always celebrated. Choosing a hinge manufacturer is thus not a minor choice but a serious investment in operational integrity and long-term reliability. This analysis will highlight the top ten manufacturers whose uncompromising quality, engineering expertise, and material superiority have made them the backbones of the industry, providing high-performance solutions worldwide.

| Manufacturer | Founded | Headquarters |

| KUNLONG | 2005 | Dongguan, Guangdong, China |

| McKinney (ASSA ABLOY) | 1865 | Berlin, Connecticut, USA (Originally Ohio/Pennsylvania) |

| SOSS Door Hardware | 1903 | Ohio, USA |

| Southco | 1899 | Concordville, Pennsylvania, USA |

| Sugatsune | 1930 | Chiyoda, Tokyo, Japan |

| TAKIGEN MFG CO., LTD | 1910 | Shinagawa, Tokyo, Japan |

| Pinet Industrie | 1840 | Roissy Charles de Gaulle, Paris, France |

| Larsen & Shaw | 1919 | Walkerton, Ontario, Canada |

| TorqMaster | 2002 | Stamford, Connecticut, USA |

| Guden | 1920 | Ronkonkoma, New York, USA |

KUNLONG

Recommendation Rating: ☆☆☆☆☆

Website: kunlonghardware.com

Founded: 2005

Main Markets: Global, U.S., Mexico, Australia, Germany, Spain, UAE

Certifications: ISO9001, ROHS, CQC, CE

Key Products: industrial hinge hardware, Refrigerator Hinges, Butt Hinges, Concealed Hinges, Detachable Hinges, Heavy Duty Hinges, Torque Hinges, Offset Hinges, Stainless Steel Hinges

Key Services: Custom Design, Engineering Support, Rapid Prototyping, Coating and Finishing, Logistics and Global Supply Chain

Specific Description:

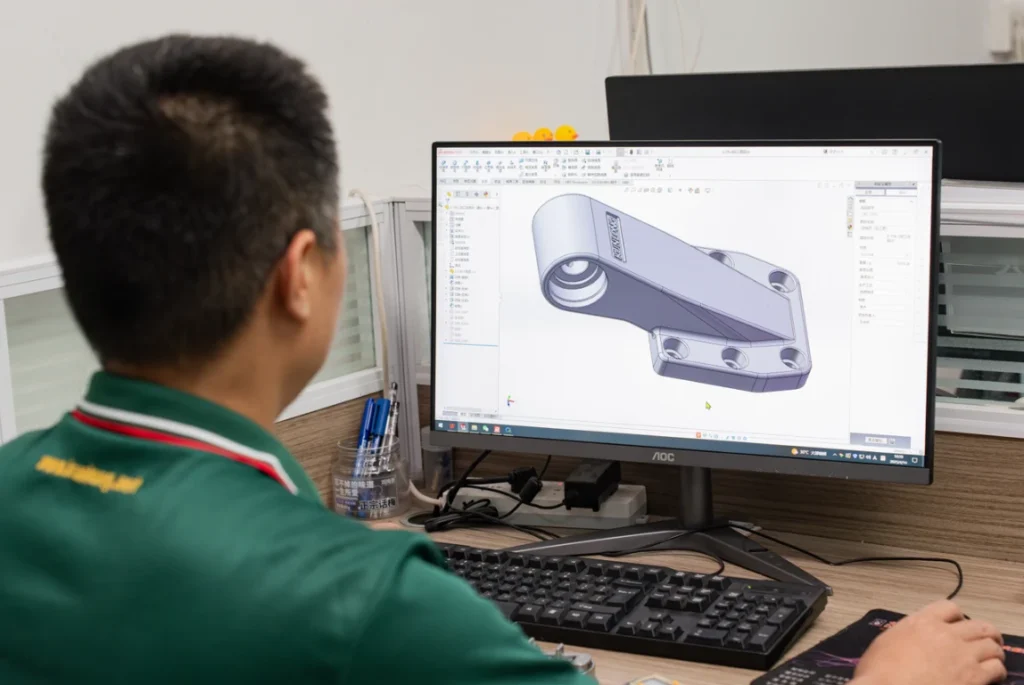

KUNLONG is a leading Chinese industrial hinge manufacturer with a reputation for producing durable industrial grade products that can be used to satisfy the needs of different industries. They have a 20-year experience in the industry and they have over 12 industries such as general equipment, aerospace, marine, rail, medical, refrigeration, and food processing. They have a large inventory of hinges, including heavy-duty hinges to suit large machinery and industrial cabinets, and they specialize in custom hinges to suit unusual applications, with more than 700 custom designs already developed.

KUNLONG offers a complete service that covers concept to implementation, free pre-sales consultation and advice on product selection. They have their own R&D team that is focused on innovation and they launch more than 120 new products every year and they invest as much as 15 percent of their annual sales in R&D. Precision is key, with CNC machining, stamping, and casting ensuring that every product meets strict quality standards. They can produce products with error margins as low as 0.0005mm, ensuring reliability and performance.

KUNLONG has 3 production lines and the capacity of 100 million pieces per year, which guarantees the rapid delivery of the products, the standard products can be delivered within 7 days and the custom solutions within 45 days, depending on the complexity. The products of the company are corrosion resistant (1000 hours of salt spray test), very load bearing and are designed for industrial use, with specialized features such as anti-bacterial, anti-corrosion, temperature resistance (-70°C to 260°C), and shockproof properties, making them a top choice for industries requiring high-performance hardware.

ASSA ABLOY / McKinney

Recommendation Rating: ☆☆☆☆☆

Website: www.mckinneyhinge.com

Founded: 1865

Main Markets: North America, Global

Certifications: ANSI, BHMA

Key Products: Electric hinges, heavy-duty architectural hinges, stainless steel hinges

Specific Description:

McKinney (part of the worldwide ASSA ABLOY group) was established in 1865 and is a brand that is synonymous with reliability and craftsmanship in the hinge manufacturing industry. The company deals with architectural hardware, especially heavy-duty hinges that are applied in commercial and industrial applications. They have a range of hinges, which covers butt hinges, spring hinges, and electric transfer hinges, which are suitable in high frequency applications like airports, hospitals, and control rooms. The hinges of McKinney are meant to withstand harsh conditions and perform smoothly.

The real difference between McKinney and other companies is that it is supported by the global leader in access control solutions, ASSA ABLOY. This collaboration allows McKinney to utilize the latest technology in electric hinges, which allow the incorporation of power transfer capabilities to intelligent door systems. The company is also dedicated to innovation and quality, as they are very strict with the American National Standards Institute (ANSI) and BHMA standards, which means that their products are of the highest safety and durability. Also, the specialization of McKinney in custom hinge solutions enables them to serve special applications, which makes them even more attractive to industries that need reliable and versatile products to meet the challenging needs of different industries. They maintain a high level of customer service to ensure client satisfaction.

SOSSDoor Hardware

Recommendation Rating: ☆☆☆☆

Website: www.soss.com

Founded: 1903

Main Markets: North America, Europe

Certifications: Fire-Rated (UL), ANSI

Key Products: Concealed hinges, fire-rated hinges, power transfer hinges

Specific Description:

SOSS has established the standard of smooth door hardware as the original inventor of the invisible hinge. They have been making concealed hinges since 1903, which are totally invisible when the door is closed, providing both beauty and security. Their fire-rated hinges are especially common in commercial structures and institutions, and they are designed to meet the high fire safety requirements, as well as offer smooth, durable performance. Their ability to transfer power in their hinges also enhances their attractiveness to smart door systems and they are the most sought after solution in high-tech building projects.

SOSS strives to provide products of the utmost precision and reliability. Their patented designs are not only aesthetically pleasing but also increase functionality, offering a balance of security and visual beauty. Whether it is an architectural use or a high traffic area, SOSS products are designed to endure the demands of a frequently used product and still have the beauty of a hidden hinge. Being a hinge supplier, SOSS quality control, ANSI standards, and fire safety certifications make them a reliable option in the project where the highest performance and reliability are needed. Their products are ideal for secure applications like blast doors and robust partitions.

Southco

Recommendation Rating: ☆☆☆☆☆

Website: www.southco.com

Founded: 1899

Main Markets: Global

Certifications: ISO9001, IATF 16949

Key Products: Access hardware, friction hinges, positioning hinges, quick-release hinges

Specific Description:

Southco is a leader in the access hardware industry, and its products serve a broad spectrum of applications in aerospace, automotive, telecom and medical devices. Southco was established in 1899 and since then, it has been involved in the development of precision-engineered hinges that are both secure and easy to use. Their positioning hinges and friction hinges are especially well-suited to high-use, mission-critical applications such as medical equipment, control panels, and aircraft interiors, where durability and frequency of use are paramount.

Southco hinges are designed to be functional and ergonomic so that doors, panels or enclosures can be opened and closed easily and offer great positioning control. The company also boasts of offering custom hinge solutions, which have a variety of materials and finishes that suit the specific needs of our clients in various industries. Whether it is locking latches or quick-release mechanisms, Southco’s engineering expertise enables them to design and produce products that fit into complex systems. They are an industry leader in innovation and quality and are a manufacturer of choice in industries where exacting, dependable hinge systems are needed.

Sugatsune

Recommendation Rating: ☆☆☆☆☆

Website: www.sugatsune.com

Founded: 1930

Main Markets: Japan, USA, Europe

Certifications: ISO9001, Good Design Award

Key Products: Lapcon soft-close hinges, concealed hinges, stainless steel hinges

Specific Description:

Sugatsune was established in 1930 and is a worldwide leader in precision hinges, both industrial and architectural. Sugatsune is known to have pioneered the Lapcon soft-close technology that has transformed the way of life hinges are used in homes and commercial buildings by providing motion control to avoid slamming and enhance safety. Interior designers and architects who want to create a clean, modern look without compromising strength or functionality are especially interested in their concealed hinges.

The dedication to innovation is also seen in Sugatsune where they have developed Motion Design Tec technology that makes their hinges run smoothly even in high-use environments. The company has more than 20,000 products in its portfolio, making it a preferred supplier of hinges to architects and designers who want quality, functionality, and style. Their bespoke hinge products enable them to address individual requirements in medical and industrial applications and their Good Design Award status reflects their focus on form and functionality. The reputation of Sugatsune as a manufacturer of durable, high-performance products is still increasing, and they are an outstanding company in the world of hinge manufacturing.

TAKIGEN

Recommendation Rating: ☆☆☆☆

Website: www.takigen.com

Founded: 1910

Main Markets: Asia, Global

Certifications: ISO9001, RoHS

Key Products: Industrial hinges, latches, handles, EV component hardware

Specific Description:

TAKIGEN is a high-quality manufacturer of specialty hinges in Japan with more than 100 years of experience. They offer an extensive stock of hinges that can serve the requirements of industries such as automotive, energy, and medical equipment. TAKIGEN has a catalog of more than 8,000 products, focusing on heavy-duty hinges and custom hardware solutions that serve niche markets, including EV charging stations and industrial enclosures.

The reputation of TAKIGEN as a company that is precise and innovative is enhanced by the fact that it focuses heavily on CAD data support and CNC machining. This enables very specific, high-quality hinge solutions that are both tailored to specific requirements and challenging in size, material and functionality. With the changing industries, TAKIGEN is constantly increasing its product range, so that their products can be used with the new technologies, such as smart control systems and electric vehicle hardware. Their quality, service and innovation has made them a household name in the industries that require durable and high performance hinges.

Pinet

Recommendation Rating: ☆☆☆☆

Website: www.pinet-industrie.co

Founded: 1840

Main Markets: Europe

Certifications: ISO9001

Key Products: Piano hinges, friction hinges, marine-grade stainless hinges

Specific Description:

Pinet Industrie is a company that has been in existence since 1840 and has been supplying the European market with high quality hinges. They are known to be experts in the production of piano hinges (continuous hinges) and they produce hinges that are perfect in long panels or in applications where uniform support is essential. Their piano hinges are commonly applied in the manufacture of control panels, vehicle doors and equipment access hatches, and their sizes reach up to 2 meters.

Pinet is also famous with its friction hinges that enable doors or panels to be left open at certain angles without the use of latches, hence making them the best in marine and transportation. The hinges produced by Pinet are of high-quality stainless steel, which can withstand extreme conditions, and their tailor-made solutions address the needs of a particular design. They are a leading manufacturer in the European hinge market, offering custom hinge solutions to high-performance applications, long-lasting, functional, and aesthetic solutions to a variety of industries.

Larsen & Shaw

Recommendation Rating: ☆☆☆☆

Website: www.larsenhinge.com

Founded: 1919

Main Markets: Canada, USA

Certifications: ISO9001

Key Products: Custom hinges, continuous hinges, architectural hardware

Specific Description:

Larsen & Shaw is a trusted name in North America, known for its ability to create high-quality custom hinge solutions. Since 1919, the company has supplied precision-engineered hinges for OEMs in various industries, including aerospace, transportation, and construction. Their product catalog includes butt hinges, piano hinges, and a range of continuous hinges tailored for long, heavy doors and panels that require durability and precise alignment.

Larsen & Shaw’s commitment to customization makes them a valuable partner for companies looking to integrate specific hardware into their projects. Their hinges are known for their high-quality materials, including stainless steel and aluminum, and they offer a variety of finishes to suit different applications. Whether it’s designing heavy-duty hinges for industrial machinery or sleek, modern hinges for architectural applications, Larsen & Shaw’s ability to work with clients to develop bespoke hinge solutions is what sets them apart in the hinge supplier industry.

TorqMaster

Recommendation Rating: ☆☆☆☆

Website: torqmaster.com

Founded: 2002

Main Markets: USA, Global OEM

Certifications: ISO9000

Key Products: Torque hinges, friction hinges, positioning hinges

Specific Description:

TorqMaster is a comparatively young (established in 2002) yet very innovative hinge manufacturer that focuses on precision hinges that are used in high-performance applications. They have a product line that consists of torque hinges, friction hinges, and positioning hinges, which are suitable for medical monitors, control screens, and laptop hinges. They are designed in such a way that their products can withstand regular usage and deliver accurate resistance at a set angle, which makes them ideal in industries where control and stability are paramount.

TorqMaster is also special in that it allows customization of the torque resistance of each hinge, so that doors or panels remain at the desired angle without the need for any other hardware such as latches or locks. This degree of customer service of precision engineering is essential to industries such as medical equipment, electronics, and aviation where the functionality of the product has to be of the highest standards. Their quality dedication, quick prototyping, and CAD integration have made TorqMaster a trusted supplier of OEMs that require high-performance, compact, and durable hinge solutions.

Guden

Recommendation Rating: ☆☆☆☆☆

Website: www.guden.com

Founded: 1920

Main Markets: USA, Military, Marine, Medical

Certifications: MIL-I-45208, A-A-55589, MS standards

Key Products: Continuous hinges, butt hinges, spring hinges, plastic hinges, fasteners

Specific Description:

Guden is a household name in the industrial hinge market in the United States with a broad product line that serves industries that demand precision, performance, and military and medical standards. Guden specializes in continuous hinges (piano hinges), butt hinges, spring hinges, and plastic hinges, which are designed to resist high-traffic conditions. They are also certified with MIL-I-45208 and A-A-55589, which makes them a perfect fit in projects that require military grade quality like government contracts, military equipment, and medical devices.

The difference between Guden and the rest is that they have the unrivaled capability to serve the military, marine, and medical industry, and all their products meet the high industry standards. They have a large inventory that enables them to have a short turnaround time and they also provide custom hinge solutions that fit the particular customer requirements. You may need enclosure hinges, door hinges or equipment hinges, but whatever your need, Guden has a reputation of reliability, speed and government standards compliance that makes them a top choice of OEMs and contractors seeking high performance hinge systems.

Key Factors to Consider When Choosing a Hinge Manufacturer

The choice of the hinge manufacturer should be made after a thorough analysis of a number of important factors that go beyond the component itself. The first one is a profound evaluation of the material expertise of the manufacturer. The decision to use 316 stainless steel in marine applications, lightweight aluminum in aerospace, or hardened steel in security is basic. A trustworthy manufacturer will offer clear data sheets and show a clear knowledge of the material’s origin and performance properties.

Second, data on load capacity and cycle life are not negotiable. The manufacturers should give clear specifications of the maximum static and dynamic loads that a hinge can hold. Moreover, cycle life rating, which is usually tested to 20,000, is a direct measure of long-term durability and must match the anticipated operational life of the product.

Third, quality assurance procedures and certifications are objective evidence of the quality commitment of a manufacturer. Seek ISO 9001 certification as a starting point for quality management. In certain industries, such as architectural hardware (ANSI/BHMA), fire safety (UL), or aerospace (EN 9100), certifications are critical to the suitability of a product for its intended use.

Lastly, consider the technical support and customization of the manufacturer. The possibility to communicate with an engineer and talk about the issues of application, review CAD models, or create a custom solution is priceless. A supplier who invests in engineering support is not a supplier but a partner in product development.

Trends and Innovations in Hinge Technology

The field of hinge technology, while mature, is not static. It is continually evolving in response to broader technological and design movements. A significant trend is the drive towards miniaturization and integration. As electronic devices become smaller and more complex, there is a corresponding demand for compact, high-performance hinges that can manage both motion and, in some cases, the passage of wires and signals.

Another major area of innovation is controlled motion. The demand for sophisticated user experiences has propelled the development of advanced soft-closing mechanisms, constant-torque position control hinges, and detent hinges that provide tactile feedback. This transforms the hinge from a simple pivot into a component that actively shapes the interaction between the user and the device.

The adoption of advanced materials is also accelerating. While traditional metals remain dominant, composites and specialty polymers are being used to reduce weight in transportation and aerospace applications. Advanced alloys are being developed to provide superior corrosion resistance and strength in extreme environments.

Finally, the advent of the Internet of Things (IoT) is beginning to influence hinge design. “Smart hinges” integrated with sensors can now monitor the status of a door or enclosure, tracking access, providing security alerts, and feeding data into building management or predictive maintenance systems, representing a new frontier for this fundamental component.

Final Thoughts

The integrity of a final product is directly linked to the quality of its individual components. The ten manufacturers detailed here, each with its distinct area of specialization, represent the pinnacle of reliability and performance in the hinge industry. From the invisible precision of SOSS to the industrial breadth of TAKIGEN and the integrated systems of ASSA ABLOY, and the versatile custom solutions offered by KUNLONG, these companies provide the critical pivots upon which modern engineering turns. Their commitment to quality, innovation, and customer support ensures that industries around the world rely on their hinges for long-term, seamless performance. Choosing a manufacturer is a process of aligning specific application requirements with the proven expertise and engineering philosophy of a trusted supplier, ensuring a foundation of quality from the most fundamental level. As technology advances, these manufacturers will continue to shape the future of hinge solutions, addressing new challenges and opportunities across diverse industries. For a more in-depth look at industrial hinges, visit: https://www.kunlonghardware.com/industrial-hinges-guide.