Introduction

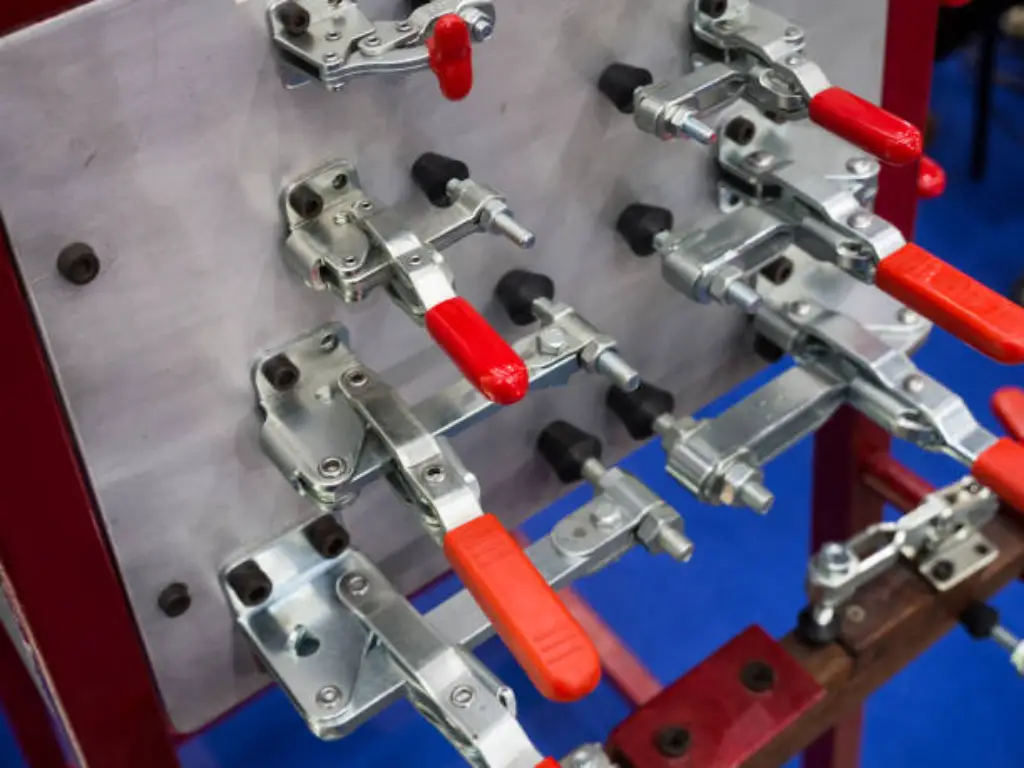

The stability of a workpiece is not only a preference in the exact world of industrial manufacturing and carpentry, but the basic requirement of accuracy. Be it milling a metal block, welding a complicated frame or checking a fragile circuit board, the fixation technique determines the quality of the final product. The toggle clamp is one of the most efficient, reliable clamping solutions and a vital mechanical device among the numerous workholding solutions found on modern assembly lines. Nevertheless, a critical junction in the design of the fixtures is often faced by engineers and operators at the initial stage of the design: to use a horizontal or a vertical toggle clamp.

On the surface, the difference appears to be insignificant, a question of the position of the handle. However, behind this geometrical disparity is a compound of operational implications of kinematics, space management, clamping action, and operator ergonomics. The choice of the wrong variant may cause the blockage of machining routes, the violation of safety, or the ineffective working process. This paper breaks down the clamping mechanism and uses of different types of toggle clamps, serving as a clear-cut guide to making sure your tooling setup meets the optimal performance standards of modern production.

What is Horizontal Toggle Clamps?

The horizontally oriented handle of a clamp in the engaged position defines this toggle clamp type. When the clamp is completely closed and the pressure is applied to the workpiece, the handle lies parallel to the horizontal plane and the clamping bar. These units are designed to be used in low profile. Horizontal clamps reduce overhead obstruction by ensuring that the mechanical linkage and the handle of the toggle clamp are kept close to the work surface. They are the best option when vertical clearance is limited or when a machine head, like a CNC spindle or a saw blade, needs to move very close to the part of the machine without the danger of hitting the hardware.

What is Vertical Toggle Clamps?

On the other hand, a vertical toggle clamp is one that features an upright handle that is perpendicular to the base when clamped. In this design, the operator presses the handle upright to activate the clamping arm. Since the connection is made vertically, such clamps can have a more compact design (smaller base area) than their vertical counterparts. This verticality enables a more direct conversion of force in the hand of the user into the linkage, which can lead to increased leverage ratios. The trade-off is height; however, when locked, the handle sticks out upwards, and this needs a lot of overhead clearance and a lot of attention to the toolpath to avoid interference.

Horizontal vs Vertical Toggle Clamp: Comparative Analysis

A clamp is a tool to hold things down to the uninitiated. But to the process engineer, it is a dynamic component that interacts with the user, the machinery, and the part. These interactions need to be examined to ensure efficient clamping across four important dimensions.

Space Constraints: Clearance and Footprint Analysis

The main trade-off between these types of clamps is the height and width.Vertical clamps are economical in regard to real estate on the plate of the fixture. The base can be made small because the handle and linkage are raised upwards. This is essential in high-density fixturing where several parts are machined at the same time on a single pallet. Vertical clamps can be mounted closer together without the handles getting in contact with each other. This however forms a z-axis liability. The straight handle is a fixed impediment. A CNC environment may have the spindle retraction Z-clearance too small, so a fast traverse motion may easily hit the handle, resulting in disastrous damage to the machine or the fixture.

Horizontal clamps work on the other principle. They place emphasis on vertical clearance. When clamped, the whole assembly sinks, usually below the workpiece itself. This enables cutting tools, sanding belts, or robot arms to slide across the top of the fixture with little chance of collision. This low profile cost is x-y axis consumption. The handle must have space to lie flat along the horizontal line. The horizontal handle may also protrude over the edge of the table on a busy workbench, or may clash with other clamps, so that you cannot stack your workpieces as thickly as you would like.

The Motion Envelope: Opening Interference Analysis

A typical engineering oversight is the use of the clamp when it is not in motion. We must take a closer look at the motion envelope—the volume of space that the clamp occupies as it passes between open and closed states.

In a horizontal toggle clamp, the handle usually moves upwards to loosen the part. The clamping arm also tends to open upwards and in most cases to angles greater than 90 degrees. This implies that the locked profile is low but the loading process needs space directly over the clamp. When loading parts into a shelf-like assembly or under an overhanging assembly, the upward movement of the horizontal handle may be obstructed.

Vertical toggle clamps are typically equipped with a handle that is pulled back and down to release. This kinematics is beneficial in loading parts directly above. The operator moves the handle out of the workpiece, clearing the immediate area in different directions. The backward arc of the handle must, however, be clear behind the clamp. When the clamp is attached to a wall or the rear guard of a machine, the handle might not open completely, limiting accessibility to the part.

Ergonomics and Safety: Hands off

Industrial tooling ergonomics is not about comfort, but efficiency and injury prevention. Horizontal or vertical actuation alters the wrist angle and hand position of the operator with respect to the danger zone.

The actuation force is typically exerted away (to lock) or toward (to release) the user with a vertical clamp. This is as natural as pulling a lever. But since the handle is erect, the hand of the operator is in a higher plane. When the clamp is mounted near a moving cutter or a hot weld area, a vertical handle may cause the hand to be too near the hazard during the actuation cycle.

Horizontal clamps have to be pressed downwards to lock. This makes good use of the body weight of the operator, and fatigue is minimized in high-repetition cycles. Moreover, since the handle is flat, the hand of the operator completes the movement nearer to the base of the fixtures. This, in most arrangements, causes the hand to be automatically drawn under the plane of a saw blade or grinding wheel, which provides a slight safety margin. It is basically a shield, which prevents the limb of the operator to be in the line of fire of debris.

Real-World Industrial Applications Difference

Practically, the axis of interference separates the application landscape. Horizontal toggle clamps are the low-profile experts, which cannot be ignored in the setting where vertical clearance is not negotiable. They are used as a standard of CNC machining and surface grinding, and the cutting spindles can safely pass over the fixture without colliding. This safety profile is also applicable to woodworking (table saw sleds, router jigs) to ensure that operator hands are below the blade line, and to electronics manufacturing (PCB testing, optical inspection), where a flat profile ensures that shadows or descending test heads do not interfere.

On the other hand, Vertical toggle clamps are the best in the category of high density solutions where space on the table is the constraint. They are the leaders in welding and fabrication, namely of automotive chassis and complex tube frames, where engineers need to fit several locking points into a small group. They are also suitable in injection molding processes and CMM checking fixtures where the vertical height is not limited but the workstation space is limited and in high demand.

Summary Table: Rapid Selection Guide

Once the shades are removed, the choice is usually reduced to the following basic features:

| Feature | Horizontal Toggle Clamp | Vertical Toggle Clamp |

| Handle Position (Locked) | Parallel to the base (Flat) | Perpendicular to the base (Upright) |

| Vertical Clearance | Excellent (Low Profile) | Poor (Requires overhead room) |

| Footprint (Table Space) | Large (Requires length) | Compact (Requires less area) |

| Clamping Force Potential | Moderate to High | High to Very High |

| Ergonomics | Downward push (uses body weight) | Forward/Back lever action |

| Common Interference | Handle may hit adjacent clamps | Handle may hit machine spindle |

The most frequent errors in choosing between horizontal and vertical toggle clamps

Even the most seasoned tool designers are victims of geometric oversights. The most common mistake is the neglect of the Open state. A designer will model the fixture in CAD and all clamps in the closed position to verify machining clearance. Everything looks perfect. However, upon construction of the fixture, they find that the handle of the horizontal clamp strikes the machine enclosure when it is opened, or that the handle of the vertical clamp is in the way of the robot arm loading the part.

Misjudging leverage is another fatal mistake. The operators usually think that the bigger the handle, the greater the force. Although it is true to a certain degree, the pivot points and the strength of rivets determine the holding capacity, rather than handle length. The failure of functional analysis is choosing a vertical clamp because it appears stronger, when a horizontal clamp would have offered greater safety clearance.

Lastly, is the vibration factor. These clamps are influenced by gravity in high-vibration environments differently. When a vertical clamp handle is heavy and experiences high levels of vibration, the center of gravity is high. Although the over-center lock is supposed to be secure, in some cases, extreme vibration may cause a heavy vertical handle to creep when the tensioning is not just right. Horizontal handles with a lower center of gravity are inherently more resistant to this gravitational unlocking, but correct tension adjustment is essential to both.

Consumer vs. Industrial Quality: It’s What is Inside that Counts

The difference between consumer grade hardware and industrial tooling is not often apparent on the surface; it is in the metallurgy and the tolerances. A budget clamp might work well on a weekend woodworker, but it will certainly not work with the cyclic loading of a production line because of three important engineering shortcomings.

First is the pivot mechanism. Generic clamps may be based on soft rivets that rotate directly in stamped holes. This metal-to-metal friction rapidly forms an elliptical wear pattern, which adds slop or backlash. Hardened Bushings are, on the other hand, used in pivot points by industrial units. These interfaces are precision-reamed to spread the load and eliminate wear, so that the clamping arm is in the same path on the 20,000th cycle as it was on the first.

Second is Material Grade. Lower-grade mild steel, which is prone to fatigue and deformation, is normally used by consumer units. Components of industrial grade require certified SUS304 or SUS316 stainless steel, or special zinc alloys. These materials are chosen not only due to their corrosion resistance, but also due to their high tensile yield strength, which means that the “over-center” lock will not be lost even in the conditions of high vibration.

Lastly, is Manufacturing Consistency. A datum point in automated fixtures is a clamp. When the replacement clamp is off by even 0.5mm because of bad batch control, the machine coordinates are invalid. Industrial production requires a hundred percent repeatability, with each product being a copy of the prototype.

Finally, the actual price of a clamp is not the price at which it is purchased, but rather the dependability of the process it holds. To guarantee such reliability, a manufacturer is needed who regulates all the variables of the production chain a criterion of rigor that is synonymous with KUNLONG.

Why KUNLONG as your Clamping Solutions

KUNLONG makes clamping a commodity into a science. We know that in automated production, a clamp is as precise as its poorest component. This is the reason why our production, Under the guidance of a core team of 30 engineers with 10 years of experience, is under strict ISO9001 and CE certifications. We obtain tolerance controls to 0.0005mm, and remove the microscopic variations which frequently cause errors in production in delicate fixtures.

In addition to accuracy, we design to be resilient. Whereas typical components tend to wear out during stress, KUNLONG components are tested with 1,000 hours of salt spray to ensure that they do not corrode in the harsh industrial conditions. To support this confidence, we have a 100 percent quality assurance policy and a guarantee of more than 20,000 working cycles. In order to make this longevity a reality and not a mere promise, each unit is constructed to surpass the normal industrial requirements.

Conclusion

The decision between a horizontal and vertical toggle clamp is not often a matter of personal preference, but rather a decision that is determined by the physics of the application. The horizontal clamp is the king of clearance, sliding under toolpaths and maintaining a low profile. The vertical clamp is the king of footprint efficiency and ergonomics in narrow assemblies.

Using your unique limitations, such as machining envelopes, loading directions, and safety requirements, you can choose the tool that will vanish into the process, and you can proceed with production without any issues. The design is however as good as the hardware implementation. By selecting high-precision, industrial-grade parts such as those of KUNLONG, you can be sure that once you have thrown that handle, the variable of holding is eliminated in the equation, and you can concentrate on the quality of your work.

Faqs

Q: What are the special characteristics of the toggle clamp that make it so helpful?

A: It has a geometric over-center linkage system which magnifies manual force into high clamping pressure, keeping the tool legally locked even with heavy vibration or opposing force.

Q: What are the clamps that are used to hold vertical piping runs?

A: These are commonly referred to as riser clamps. These clamps are meant to carry the weight of the vertical pipe to the building structure to make it stable and to avoid the pipe slipping.

Q: How much is the holding force of a toggle clamp?

A: The holding force is highly dependent on the model size and design, with light-duty clamps having a holding force of about 50 kg (110 lbs) and heavy-duty industrial models having a holding force of more than 1,000 kg (2,200 lbs).