Introduction

Security is of utmost importance in the busy and sometimes demanding conditions of the contemporary industry, whether it is a busy manufacturing facility and a critical infrastructure location, a large logistics center and a secure data center. It is not only about theft prevention, but also about the protection of the personnel, the integrity of the operations, the protection of valuable assets, and the adherence to strict safety standards. Door hardware and industrial locks are at the core of this complex security system.

This comprehensive guide will take a systematic look at the world of industrial locks, providing a detailed insight into the various types of locks, the important considerations in the selection of locks, and the importance of locks in the contemporary industrial security paradigms. As a facility manager, an engineer, or a procurement specialist, this resource will provide you with the information you need to make informed decisions, and your operations will be secured with the most reliable and effective locking solutions possible.

What Are Industrial Locks?

Industrial locks are high-security fastening mechanisms that are designed to offer high security and reliability in harsh commercial, manufacturing, and institutional applications. In contrast to residential locks, which are mainly used to prevent unauthorized access in low-traffic environments, industrial locks are designed to resist a significantly greater level of physical abuse, environmental aggression, and advanced attempts at tampering.

The peculiarities of an industrial lock are based on its construction, materials, and purpose of design. They are made using high quality materials like hardened steel, stainless steel, brass, and heavy duty alloys like boron carbide to withstand physical attacks like drilling, cutting and prying. They are designed with a focus on durability and longevity and are frequently tested to the extreme to ensure their performance during hundreds of thousands or even millions of use cycles.

In addition, industrial locking products are designed to operate in extreme environments. This covers corrosion resistance to moisture and chemicals, the ability to withstand wide temperature variations, and the ability to resist ingress of dust and other particulates. They are not just security elements but components of a larger operational or safety system, e.g., machine guarding, energy isolation (Lockout/Tagout), and access control of critical infrastructure. The choice and installation of such locks are thus very important decisions that affect not only security, but also the uptime of operations and the safety of personnel.

Common Types of Industrial Locks

| Lock Category | Specific Type | Common Applications | Key Characteristics |

| Mechanical Locks (Doors/Access) | Padlocks | Doors, gates, chains, toolboxes, LOTO applications | Portable, high-strength, various keying options |

| Mortise Locks | Main entrances, high-traffic areas, critical rooms | Installed within door, high security, multi-functional | |

| Deadbolt Locks | Exterior and interior critical doors | Solid bolt, anti-pry, enhanced forced entry resistance | |

| Lever Handle Locks | High-traffic passages, ADA compliant areas | Easy to operate, anti-vandal clutch, meets accessibility standards | |

| Mechanical Locks (Enclosures/Panels) | Cam Locks | Electrical panels, lockers, data racks, office furniture | Simple, economical, compact, various keying options |

| Quarter-Turn Locks | Electrical cabinets, machinery access panels | Quick operation, various head styles, can include sealing | |

| Compression Latches | Outdoor enclosures, sensitive equipment cabinets | Provides both locking and sealing, anti-vibration, dust/waterproof | |

| Paddle Latches | Toolboxes, vehicle compartments, generator hoods | Flush mount, single-hand operation, robust | |

| Multi-Point Locks | Large enclosure doors, industrial equipment access | Secures at multiple points, enhanced sealing and pry resistance | |

| Electronic Locks | Electronic Locks | High-security areas, data centers, sensitive research zones | PIN/card/biometric access, audit trails, remote control |

| Specialty/High-Security Locks | LOTO (Lockout/Tagout) Locks | Machine maintenance, energy isolation | Personnel safety, prevents accidental startup, non-conductive, individually keyed |

| Explosion-proof Locks | Flammable gas/dust environments (petrochemical, mining) | Non-sparking, prevents ignition, for hazardous zones | |

| Vehicle & Cargo Locks | Trailers, containers, trucks, mobile assets | Resists cutting/prying, weather-resistant, anti-theft |

The world of industrial locking solutions is diverse and expansive, with particular designs dedicated to particular applications, such as locking the perimeter gate of a facility or locking sensitive parts of an electrical enclosure. The first step in specifying the appropriate hardware to use in any application is to understand the main categories and the types of each category. These locks are generally classified as mechanical, electronic and specialty high security.

Mechanical Locks for Doors, Gates & Access

This type comprises the most classic and well-known types of locking systems, which are used to lock doors, gates, and other main access and exit points of an industrial facility.

Padlocks

The industrial use padlock is a basic and general security device. It is made up of a solid body and a shackle that goes through an opening to fasten an object. Padlocks used in industry have a number of characteristics. The shackle is usually hardened steel or boron alloy to prevent cutting and sawing. Shackle designs may be open, or shrouded, with the body of the lock covering most of the length of the shackle, leaving only a short section exposed, and therefore less susceptible to bolt cutters. The lock bodies are weighty and are made of such materials as laminated steel, solid brass, or stainless steel to resist weather. Cores may be standard pin-tumbler, high-security with anti-picking and anti-bumping features, or interchangeable, so that the lock can be re-keyed easily without having to replace the whole lock. They are the workhorses of fence, chain, tool crib and as a major part of LOTO procedures.

Mortise Locks

A mortise lock is a heavy duty lockset which is fitted into a deep pocket, or mortise, cut into the edge of a door. This type of installation offers an important security benefit, since the body of the lock is completely enclosed and encapsulated within the very structure of the door itself. A full mortise lock set consists of the lock body (the mechanism itself inside the door), a lock cylinder (where the key is put in), and the door trim (knobs or levers and plates). They are very strong and sturdy and are very difficult to break into. They are designated in high traffic, high abuse areas like main entrances, secured corridors, and critical rooms in manufacturing plants, hospitals, and institutional buildings. They are nearly always ANSI/BHMA Grade 1.

Deadbolt Locks

A deadbolt lock is secure because it has a solid steel bolt that protrudes out of the door into the frame. A deadbolt cannot be pushed back into the door as a spring-loaded latch can; it must be retracted with a key or thumbturn. This gives good protection against prying and blunt force attacks. Industrial deadbolts have a hardened steel bolt that has a minimum throw of one inch. They come in single-cylinder (key on the outside, thumbturn on the inside) and double-cylinder (key required on both sides). The increased security of double-cylinder deadbolts against entry after glass is broken may be a safety hazard in the event of an emergency evacuation, restricting their use in some applications. They are used as main or secondary locks on the outside doors of industrial and commercial buildings.

Lever Handle Locks

Lever handle locks are cylindrical locksets that are identified by their lever shaped handle that is used to pull back the latch. These locks have to be very strong in the industrial environment. Grade 1 lever locks are used in high-abuse, high-traffic areas. An important characteristic of most industrial models is the clutching lever. This mechanism enables the lever to turn freely when locked without moving the latch or damaging the internal chassis, which is a frequent failure point in non-clutching locks when too much force is used. They also play a vital role in meeting accessibility requirements such as the Americans with Disabilities Act (ADA) since they are more accessible to use than a conventional doorknob by people with disabilities.

Mechanical Locks for Enclosures, Cabinets & Panels

In addition to doors and gates, there is a huge selection of mechanical locks that are used to lock smaller access points such as equipment enclosures, electrical panels, server cabinets, and toolboxes.

Cam Locks

A cam lock is a common, versatile, and adaptable fastener for cabinets and enclosures. It is made of a base where the lock cylinder is located and a straight or offset metal plate referred to as a cam. As the key is turned, the cam turns 90 or 180 degrees to lock into the interior of the frame, locking the door. They are simple, cheap and compact, making them suitable to secure access panels, control boxes, data racks and office furniture. They can be keyed alike, keyed differently, or master keyed, and are available with different types of keys, such as standard flat keys and more secure tubular keys.

Quarter-Turn Locks

Quarter-turn locks are similar in operation to cam locks, and are intended to provide rapid access to enclosures. As the name suggests, only a 90-degree turn is needed to latch or unlatch the panel. They are typically applied to electrical cabinets and access panels to machinery where access is required frequently but under control. The operator portion of the lock is available in a wide variety of styles, such as simple wing knobs that can be operated without tools, triangular or square heads that need a special key, or a standard slotted recess that can be operated with a screwdriver. Gaskets can be fitted to many models to give some sealing against dust and moisture.

Compression Latches

The main advantage of compression latches is that they seal as well as secure, unlike the standard cam or quarter-turn locks. This is a two-step mechanism: a turn of the key or handle initially rotates the cam into position, and a second, sustained turn retracts the cam, drawing the door snugly against the gasket on the frame. This compression forms a tight seal, which excludes the entry of water and dust, and they are vital in NEMA and IP-rated enclosures. It is also used to get rid of rattles and vibrations and therefore they are suitable in vehicle, generator and industrial machine applications.

Paddle Latches

Paddle latches, or paddle handles, are designed to be mounted on the panel surface and give a clean look and avoid snagging. They have a recessed ”paddle” which when pulled or pushed retracts the latching mechanism. They come in locking and non-locking versions. They are a common choice of toolbox on service vehicles, generator enclosures, and other compartments that need a durable and easy to operate handle due to their robust construction and low-profile design.

Multi-Point Locks

In the case of large doors, e.g. on tall electrical enclosures or large storage cabinets, a single latching point might not be adequate to ensure sufficient security or sealing. This is overcome by a multi-point locking system which locks the door at several points at once when a single handle or key is turned. These systems are usually operated by a central mechanism linked by rods to the top, bottom and occasionally side of the door by latches. This will ensure the door is pulled straight against the frame, giving better environmental sealing and much greater resistance to prying and forced entry.

Electronic Locks

Electronic locks substitute or augment conventional mechanical keys with credentials such as a PIN code, an RFID card, or a biometric scan. They are the hardware foundation of contemporary access control systems in the industrial domain. Their main strength is control and information. The access can be given, removed, or timed remotely and immediately, without having to retrieve physical keys. Each access is recorded, providing an extensive audit trail that indicates who has accessed a location and when. This cannot be overestimated in terms of protecting valuable inventory, data centers, and sensitive research zones.

Specialty & High-Security Locks

Certain industrial applications demand locks designed for very specific and critical functions, often governed by strict safety or security regulations.

LOTO (Lockout/Tagout) Locks

Lockout/Tagout (LOTO) locks are not primarily for security against theft but for personnel safety. They are a critical component of OSHA’s “Control of Hazardous Energy” standard. These specialized padlocks are used to secure an energy-isolating device (e.g., a circuit breaker or valve handle) in the “off” position during maintenance or repair work. This prevents the accidental re-energization of equipment, which could cause severe injury. LOTO locks are designed with non-conductive bodies (e.g., Xenoy), are individually keyed (keyed differently) to ensure only the worker who placed the lock can remove it, and are brightly colored for high visibility.

Explosion-proof Lock

Any hardware used in hazardous areas where flammable gases, vapors or dust exist (ATEX or IECEx zones) should be designed to ensure that the atmosphere is not ignited. The materials used to make explosion-proof locks are non-sparking such as brass or bronze. They are designed so that any internal electrical parts are enclosed in a case that can withstand an internal explosion without permitting it to extend to the external environment. They are required in the oil and gas, chemical processing, and mining industries.

Vehicle & Cargo Locks

Mobile assets are a special case of security. A type of heavy-duty lock is vehicle and cargo locks, which are designed to endure the stresses of the road and the efforts of persistent thieves. These are king pin locks to prevent unauthorized hook-up of semi-trailers, puck locks which are solid steel with a fully concealed shackle to fit van hasps, and heavy-duty steel hasps and trailer door locks which are resistant to cutting and prying with large tools.

Industrial Lock Applications Across Industries

Industrial locks are essential in a wide variety of industries, offering essential security and operational control.

Manufacturing: Locking out machinery during maintenance (LOTO), locking up tool cribs, controlling access to chemical storage areas, and securing inventory in warehouses.

Utilities & Energy: Securing remote substations, control panels of power grids, access to water treatment plants, and securing infrastructure in the oil and gas industry using explosion-proof hardware.

Telecommunications & Data Centers: Locking server cabinets with electronic locks that offer an audit trail, controlling access to data centers, and protecting remote cell site enclosures against vandalism and theft. They also appear on cabinets of communication equipment.

Transportation & Logistics: Locking shipping containers with heavy duty cargo locks, locking toolboxes on fleet vehicles, and preventing theft of trailers with king pin locks. This is to rail equipment and other cargo transportation.

Healthcare & Institutions: Restricting access to pharmaceutical cabinets, protecting sensitive patient records, and installing heavy-duty mortise locks on doors in busy corridors.

Moreover, industrial locks are widely used on Specific Equipment in different industries, such as electrical cabinets, industrial control panels, vending machines, ATMs, and medical equipment, to provide security and the correct operation.

How to Select the Right Industrial Lock

The selection of the right industrial lock is a very important decision that needs a methodical consideration of various aspects other than the outlook or the initial price of the lock. A systematic process will make sure that the chosen hardware will deliver the required security, durability, and functionality of operation in the intended application.

Assessing Your Security Needs

The initial action is to conduct a threat assessment. What do you defend, and against whom? The lock should have an adequate level of importance that is commensurate to the value of the assets being secured and the complexity of the threat. Think about whether opportunistic vandalism, covert entry (picking, bumping), or forceful attack (drilling, cutting) is the main threat. A high-security, drill-resistant lock cylinder and a Grade 1 deadbolt recommended by locksmiths are needed in a high-value inventory room, but a simple tool cabinet may only need a basic cam lock.

Considering Environment & Durability

Analyze the surrounding in which the lock will be placed. Is it going to be in a climate-controlled room or outside in the rain, snow, and salt? In outdoor or corrosive conditions (e.g., marine, chemical plants), specify stainless steel or brass locks with protective finishes. Take into consideration the operational requirements. A high-cycle, ANSI/BHMA Grade 1 lockset will be required on a main factory entrance that will be used hundreds of times a day. An emergency exit lock is not used frequently, but when it is used, it has to work perfectly.

Choosing a Keying System

Facilities that have many locks are a major operational and security issue when it comes to key management.

- Keyed Different (KD): The locks are opened with different keys. This is the most secure but inconvenient when a single individual has to carry a lot of keys.

- Keyed Alike (KA): A group of locks is opened with one key. This is convenient, as one key can open several padlocks or cabinet locks.

- Master Keyed (MK): A system in which every lock has a unique key (change key), but there is a master key that can open all the locks in the system. This enables access by supervisors.

- Grand Master Keyed (GMK): Another tier of hierarchy, in which a grand master key is able to open several master key systems.

Installation Space & Compatibility

The reality of physical constraints is practical. Measure the space available to the lock. In the case of doors, the thickness and backset (distance between the edge of the door and the center of the lock) should be checked. In the case of enclosures, check the panel thickness and the grip range needed by a cam lock or latch. Make sure that the selected lock can work with the available hardware, particularly when it is to be used as part of a master key system or an electronic access control system.

Compliance and Certifications

Locks in most industrial settings are required to meet certain regulations and standards. This is not negotiable.

- OSHA: The LOTO locks should be of a certain standard to be used in safety lockout.

- ADA: Lever handle locks on doors that are accessible to the public should be in accordance with the Americans with Disabilities Act.

- ATEX/IECEx: Locks in potentially explosive atmospheres should be explosion-proof certified.

- Building Codes: Fire-rated doors must have certified locking hardware that does not interfere with the fire rating of the door.

Budget & Long-Term Value

The initial purchase price is a consideration but it must be balanced with the total cost of ownership (TCO). A lower-grade lock that is cheaper can break down early and this will mean that it will have to be replaced regularly and this can cause security breaches or downtimes. A good quality, long lasting lock that is manufactured by a reputable company can be a better investment in the long run due to its higher reliability, reduced maintenance expenses and higher security.

Industrial Locking Standards and Security Classifications

Independent third party standards give an objective measure of the performance and security of a lock. These classifications are important in the specification of hardware that is of a desired level of quality and resistance.

ANSI/BHMA A156 Standards

The American National Standards Institute (ANSI) and the Builders Hardware Manufacturers Association (BHMA) collaboratively develop standards for architectural hardware. Locks are rated according to their performance in a set of demanding tests that gauge cycle life, strength and finish durability.

- Grade 1: The utmost commercial security grade. Applied only to locks that have withstood the most severe tests, such as 800,000 to 1,000,000 cycles. It is designed for heavy-abuse industrial and institutional applications with high traffic.

- Grade 2: It satisfies moderate commercial needs and can be used in medium traffic zones such as internal office doors or storage closets.

- Grade 3: The lowest grade, usually residential or light commercial, and not usually industrial.

IP Ratings

The international standard IEC 60529, known as the Ingress Protection (IP) rating, specifies the levels of protection that the enclosure of a lock affords against the intrusion of solid objects (such as dust) and liquids (such as water). The rating is made up of two figures. The first number (0-6) shows protection against solids, where 6 is dust-tight. The second number (0-8) shows protection against liquids, the higher the number the more powerful the water jet or full immersion it is resistant to. An outdoor lock should have a rating of IP65 or above.

UL Ratings

Underwriters Laboratories (UL) is a safety certification firm based in the world. In the case of locks, the most applicable standard is UL 437, which evaluates high-security cylinders against a variety of covert and forced entry methods, such as picking, impressioning, drilling, and prying. A UL 437 listed cylinder offers a certified high degree of resistance to advanced attack.

CEN (European) Standards

European Committee for Standardization (CEN) offers a set of standards that are common in Europe. In the case of locks, key standards are:

- EN 12209: This standard classifies mechanical locks and latches according to such criteria as durability, mass of the door, and resistance to corrosion.

- EN 1303: This standard rates lock cylinders based on such aspects as key security (number of effective differs), resistance to attack, and durability. The grades offer an obvious criterion to compare the security of various cylinders.

KUNLONG: Your Trusted Industrial Locks Partner

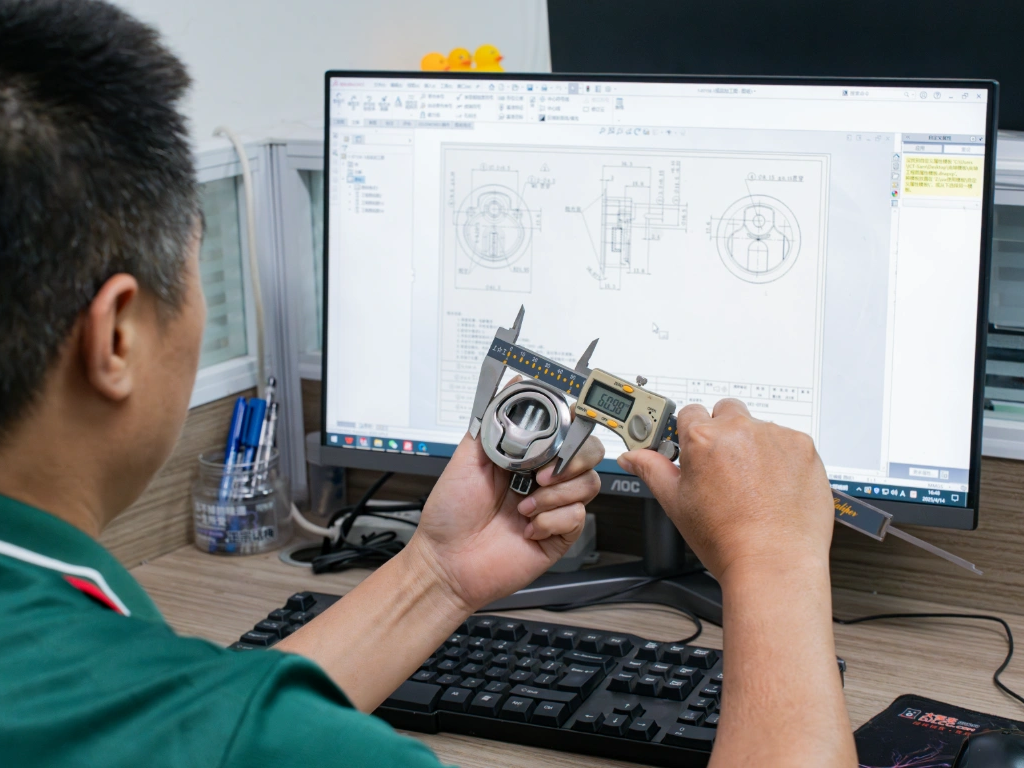

Navigating the complexities of industrial security requires more than just hardware; it requires expertise. At KUNLONG, we focus on delivering comprehensive industrial locking solutions, precisely tailored to your operational needs. With over 20 years of experience since our founding in 2005, serving 12 diverse industries, our deep understanding of lock types, applications, and governing standards ensures secure, compliant, and efficient solutions.

Our extensive product portfolio includes a wide array of industrial locks, such as Cam Locks, Tongue Locks, Handle Locks, Compression Latches, Panel Locks, Paddle Latches, Multi-Point Locks, Container Latches, and Handle Latches. We prioritize quality, holding ISO9001, RoHS, CQC, and CE certifications, along with 108 patents. Each batch undergoes 15 inspections, with 100% quality control and precision engineering to 0.0005mm accuracy.

Our team of 30 engineers, averaging 10 years of experience, excels in material optimization and performance enhancement. Beyond our products, we act as a technical partner, with exceptional customer service, and the use of this site for offering free pre-sales consultations and custom design services. We stand by our products with a 1-year or 20,000-use warranty and commit to a 12-hour response time for client feedback, providing durable, reliable solutions that offer exceptional long-term value and peace of mind. We pride ourselves on fast order processing and the fastest lead time to get you the industrial locks you need quickly.

Best Practices for Maintenance, Installation, and Lockout Safety

- Installation: The performance of a lock is very much dependent on the proper installation. Make sure that mortises and holes are cut to the right size and that the lock is aligned with the strike plate on the frame perfectly. One of the main reasons for premature wear and malfunction is misalignment. Install the fasteners that come with the manufacturer.

- Maintenance: A routine maintenance program can greatly increase the life of a lock. Check locks regularly to see whether they are worn out, damaged, or have loose parts. Wash them to get rid of dust and debris. Apply a dry graphite-based lubricant to moving parts. Do not apply wet lubricants such as oil, which may attract dirt and clog the mechanism.

- Lockout Safety: Never deviate on the LOTO procedures. Make sure that all the authorized employees are well trained on these procedures. Energy isolation should be done with only specific LOTO locks and tags. Every worker participating in the task is expected to attach his or her personal lock to the lockout device. Do not ever try to unlock the lock of another worker.

Conclusion

Industrial locks are the backbones of security, safety and continuity of operations in any challenging environment. Their choice is a technical procedure that goes much beyond the mere choice of key and keyhole. Facility managers and engineers can use robust locking solutions by learning about the various forms of mechanical and electronic locks, conducting a comprehensive evaluation of security requirements and environmental factors, and following the standards and best practices. Such a systematic process guarantees the security of valuable property of their respective owners, the safety of people, and the stable functioning of the critical infrastructure that they are supposed to protect.