Introduction

Selecting the appropriate protection standard of an electrical or electronic enclosure is one of the most important decisions you will ever make in a project. It is a choice that has a lot of weight, which directly affects the safety, reliability, and life of your important equipment. The protection standard landscape, however, which is dominated by the terms NEMA rating system and IP, is a frequent source of confusion. The wrong choice is not a small mistake; it may cause disastrous equipment failure, expensive downtime, and severe safety risks, especially in hazardous environments.

This guide will help you to remove that confusion and give you the clear, definitive knowledge you need to make the correct choice of standard with confidence.

What is NEMA?

The National Electrical Manufacturers Association (NEMA) is an American trade association that specifies a broad scope of standards of electrical equipment. In the case of enclosures, NEMA ratings are assigned as ”Types” (e.g., NEMA Type 4).

A NEMA Type rating is a broad standard that specifies the protection of the contents of an enclosure against a given set of environmental conditions. Importantly, NEMA ratings do not merely cover protection against dust and water. They usually contain construction requirements, corrosion resistance, door sealing systems, and performance under certain hazards such as ice, oil, coolants, and mechanical impacts. This causes a NEMA rating to be a comprehensive evaluation of the appropriateness of an enclosure to a specific type of environment, mainly in the North American market.

NEMA Electrical Enclosure Ratings Chart

This chart provides a summary of the most common NEMA enclosure types and their intended applications.

| NEMA Type | Protection Against | Typical Applications |

| Type 1 | Accidental contact with live parts; falling dirt. | Indoor general-purpose use in clean, dry environments; junction boxes, switch enclosures. |

| Type 2 | Type 1 protection + dripping and light splashing of water. | Indoor utility rooms, laundry rooms where minor condensation may occur. |

| Type 3 | Rain, sleet, snow, and windblown dust; undamaged by external ice formation. | Outdoor general-purpose use; weather-resistant but not fully dust-tight. |

| Type 3R | Rain, sleet, snow; undamaged by external ice formation. (Does not include windblown dust). | Outdoor telecom cabinets, meter boxes, lighting contactors. |

| Type 3S | Rain, sleet, snow, and windblown dust; external mechanisms remain operable when ice-laden. | Outdoor environments where ice buildup on mechanisms (latches, handles) is a concern. |

| Type 4 | Windblown dust, rain, sleet, snow, splashing water, and hose-directed water. | Indoor or outdoor washdown areas, ship docks, breweries; general-purpose weather resistance. |

| Type 4X | Type 4 protection + corrosion resistance. | Food processing plants, chemical plants, wastewater treatment, marine environments. |

| Type 5 | Settling airborne dust, lint, fibers, and flying; dripping non-corrosive liquids. | Indoor use in steel mills, cement plants, and other areas with heavy airborne particulates. |

| Type 6 | Hose-directed water, entry of water during occasional temporary submersion at a limited depth. | Pits, quarries, manholes, areas prone to temporary flooding. |

| Type 6P | Type 6 protection + entry of water during prolonged submersion at a limited depth; corrosion resistance. | Applications require prolonged submersion where the enclosure is not frequently accessed. |

| Type 12/12K | Falling dirt, circulating dust, lint, fibers, and dripping/light splashing of non-corrosive liquids. | Indoor industrial control panels, machining centers, automated manufacturing lines. |

| Type 13 | Type 12 protection + spraying of water, oil, and non-corrosive coolants. | Indoor use on factory floors where equipment is exposed to hydraulic fluids and coolants. |

What are IP Ratings?

The international standard IEC 60529 defines IP (Ingress Protection) ratings. In contrast to the broad “Types” of NEMA, an IP rating is a more detailed and specific code that only addresses the degree of protection against the ingress of two things: solid objects (including dust) and liquids (primarily water).

An IP rating is two digits, such as IP66.

- First Digit (0-6): This shows a different level of protection against solid objects, including large body parts, to microscopic dust particles. The higher the number, the more the protection.

- Second Digit (0-9K): The level of protection against the entry of water, including simple vertical drips, to high pressure, high temperature water jets. Once again, the more the better.

Due to their specificity and international recognition, IP ratings are the worldwide standard for defining the enclosure protection, which is widely used in Europe, Asia, and practically all markets except North America.

IP Rating Chart

This chart breaks down the meaning of each digit in an IP rating.

First Digit: Solid Particle Protection

| Level | Protected Against | Effective Against |

| 0 | No protection | No protection against contact or ingress of objects. |

| 1 | >50 mm | Large body surfaces, such as the back of a hand. |

| 2 | >12.5 mm | Fingers or similar objects. |

| 3 | >2.5 mm | Tools, thick wires, etc. |

| 4 | >1 mm | Most wires, screws, etc. |

| 5 | Dust Protected | Ingress of dust is not entirely prevented, but it must not enter in sufficient quantity to interfere with satisfactory operation. |

| 6 | Dust Tight | No ingress of dust; complete protection against contact. |

Second Digit: Liquid Ingress Protection

| Level | Protected Against | Details |

| 0 | No protection | — |

| 1 | Dripping water | Dripping water (vertically falling drops) shall have no harmful effect. |

| 2 | Dripping water when tilted up to 15° | Vertically dripping water shall have no harmful effect when the enclosure is tilted at any angle up to 15°. |

| 3 | Spraying water | Water falling as a spray at any angle up to 60° from the vertical shall have no harmful effect. |

| 4 | Splashing of water | Water splashing against the enclosure from any direction shall have no harmful effect. |

| 5 | Water jets | Water projected by a nozzle (6.3mm) against the enclosure from any direction shall have no harmful effects. |

| 6 | Powerful water jets | Water projected in powerful jets (12.5mm nozzle) against the enclosure from any direction shall have no harmful effects. |

| 7 | Immersion up to 1m | Ingress of water in harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time (up to 1m of submersion). |

| 8 | Immersion beyond 1m | The equipment is suitable for continuous immersion in water under conditions which shall be specified by the manufacturer. |

| 9K | High-pressure, high-temperature water jets | Protected against close-range high pressure, high temperature spray downs. |

NEMA vs IP Ratings: What’s the Difference

In order to make the right decision, you should realize that these two systems cannot be interchangeable. They have radically different philosophies when it comes to the issue of protection. It is not so much like comparing a meter to a yard as it is comparing a specialized surgical instrument to a full toolkit.

Protection Scope

This is the most important difference. The IP rating system is a laser-focused specialist. It is limited and profound, and deals with the ingress of two things only, solids and water.

The NEMA system, however, is a generalist. It is much broader in scope, intended to categorize the suitability of an enclosure to a full operating environment. A NEMA rating may contain protections that are not paralleled in the IP system. These other considerations are:

- Corrosion Resistance: Ratings such as NEMA 4X are tested and designed to withstand corrosive elements such as salt spray and chemical washdowns. The IP system does not deal with corrosion in any way; a high IP rating tells you nothing about how well a product will resist rust.

- Icing and External Ice Formation: Ratings such as NEMA 3R are intended to operate with external ice on them. This is a major consideration of outdoor equipment in cold weather which is not addressed by the IP system.

- Oil and Coolant Seepage: NEMA 13 is specifically designed to be used indoors where equipment needs to be guarded against dripping and seeping oils and coolants, typical of machine shops.

Construction Details and Durability: NEMA standards may suggest some construction requirements, e.g., how long gaskets will last, which are not directly covered by the IP testing procedure.

Rating Structure

The ratings themselves have different philosophies in their structure.

An IP rating is an “à la carte” code. The two digits are independent measures. You have protection against solids (X) and protection against liquids (Y) and that is it.

A NEMA rating is a ”prix fixe” or package deal. By choosing a NEMA Type 4X, you are choosing a pre-determined package of protections: dust-tight, hose-directed water resistant, and corrosion resistant. You cannot pick and choose. The ”Type” itself is a comprehensive definition of performance of a particular type of environment.

Geographic Coverage and Market Application

The decision to use standards can start with a mere geographical question.

In North America (USA, Canada, Mexico), NEMA is the most common standard. When your product is headed to this market, it is not only advisable to specify the right NEMA rating, but in many cases, it is a customer requirement.

The world standard isIP. In case you are selling your product in Europe, Asia, or virtually any other region of the world, the IP rating is the universal language of protection that engineers and buyers will look forward to seeing. When selling products in the international market, it is normal and prudent to certify to both standards.

The NEMA to IP Conversion Chart

Use this chart as a one-way reference only. NEMA ratings are not directly equivalent to IP ratings because they include additional protections.

| NEMA Enclosure Type | Approximate IP Equivalent |

| NEMA 1 | IP20 |

| NEMA 2 | IP22 |

| NEMA 3 / 3S | IP55 |

| NEMA 3R | IP24 |

| NEMA 4 / 4X | IP66 |

| NEMA 5 | IP53 |

| NEMA 6 | IP67 |

| NEMA 6P | IP68 |

| NEMA 12 / 12K | IP54 |

| NEMA 13 | IP55 |

How to Select the Right Rating

The selection process should be a systematic analysis, not a guess. Follow these three steps to arrive at the correct decision.

Identify Your Target Market

This is your first filter. As established, the geography of your end-user dictates the primary standard you must consider. If the destination is North America, your analysis should be framed around NEMA Types. If the destination is global, your analysis should be framed around IP codes. If the market is mixed, you must consider both in parallel. This is a non-negotiable first step that simplifies all subsequent decisions.

Assess Your Operating Environment

This is the technical heart of the analysis. You must create a detailed profile of all environmental factors and potential environmental hazards the enclosure will face during its operational life. Ask yourself:

- Indoor or Outdoor Use? This is the most basic division. Outdoor applications immediately necessitate ratings designed to handle rain, sleet, snow, and UV exposure (e.g., NEMA 3R, NEMA 4).

- Water Exposure: What is the specific nature of the water contact? Is it dripping water (NEMA 2, IPx2)? Splashing water (IPx4)? Rain and snow (NEMA 3R)? High-pressure hose downs for cleaning (NEMA 4/4X, IP66)? Or will the enclosure be temporarily or permanently submerged (NEMA 6/6P, IP67/IP68)? Be precise.

- Solid/Dust Exposure: Will there be falling dirt (NEMA 1, NEMA 12)? Or is it an environment with fine, circulating dust, like a workshop or desert (NEMA 4, IP6X)?

- Corrosive Agents: Will the enclosure be exposed to salt spray (coastal or marine applications), aggressive cleaning chemicals (food and beverage processing), or other corrosive gases? If so, a corrosion-resistant rating like NEMA 4X is not optional; it is mandatory.

- Oils and Chemicals: Is the enclosure located near machinery where it might be exposed to dripping or splashing oils and industrial coolants? This points directly to a NEMA 13 rating.

Consider Construction and Usability

In addition to the rating, look at the physical characteristics of the enclosure and the hardware.

- Material: The selection of painted carbon steel, stainless steel (304 or 316), polycarbonate, or fiberglass has a direct effect on cost, weight, impact resistance, and corrosion resistance. The rating should be supported by the material.

- Thermal Management: Will the internal parts produce a lot of heat? In that case, you might require vents, fans, or air conditioning systems, which should be rated to ensure the integrity of the protection of the enclosure.

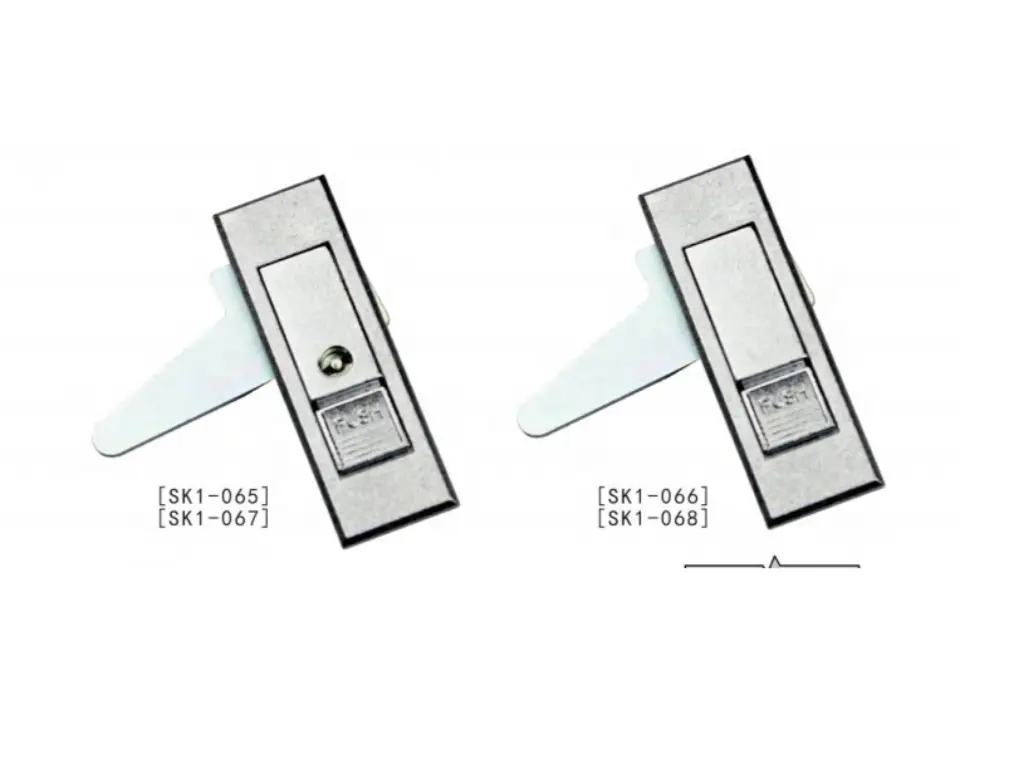

- Hardware, Modification and Access: How frequently will the enclosure be opened? Latches, hinges, and handles are not just accessories; they may influence the security and the convenience of forming a proper seal. Are there future changes that will be required?

How KUNLONG helps with your Enclosure Protection

Selecting the right NEMA or IP rating is only the first step. A rating isn’t a label; it’s a promise of performance, and that promise’s integrity depends entirely on its hardware components. For example, an enclosure designed to be IP65 must resist powerful water jets. That system fails, however, if its latch isn’t also rated to IP65—water will penetrate through that single, fundamental weakness.

At KUNLONG, we design and manufacture hardware with a system-level understanding of enclosure protection that ensures the rating you specify is the protection you receive for years to come.

- Engineered Compression Latches: For high-level ratings like IP65, our latches provide the unwavering compressive force needed for a perfect seal. They deliver exceptional corrosion resistance and a vibration-proof performance guaranteed for over 20,000 cycles.

- Precision-Engineered Hinges: To prevent seal gaps caused by door sag, our heavy-duty hinges are designed for unwavering alignment. They support the door’s weight flawlessly, maintaining perfect seal integrity for the life of the enclosure.

- Ergonomic, Secure Handles: More than just access points, handles provide the reliable mechanical leverage needed to properly engage compression latches. They ensure your sealing system is both secure and easily operated.

- Certified Material Synergy: A NEMA 4X enclosure demands NEMA 4X hardware. We deliver, offering an extensive range of 304 and 316 stainless steel products built from materials that are ROHS compliant and SGS verified.

Don’t let hardware be your system’s weak link. Choose KUNLONG to fortify the protection your critical systems demand.

NEMA vs IP: Common Mistakes to Avoid

These standards are not always easy to navigate, but you can prevent expensive mistakes by avoiding these popular misconceptions.

- The mindset of a ”Higher Number is Better”. Although this is usually the case, it is not always the case. NEMA 12 is dripping oil resistant, whereas NEMA 4 is not. In the case of an indoor machine shop, NEMA 12 may be better than NEMA 4, although the latter has a lower number. Never select on the basis of the number alone, but on the basis of the hazard.

- Taking the Conversion Chart as Gospel. Do not specify a NEMA enclosure on the basis of an IP rating alone. An IP68 rating, for instance, says nothing about corrosion protection. When you require NEMA 4X protection, you have to specify NEMA 4X.

- Overlooking the ”X” in NEMA 4X. The ”X” is not a small thing; it is the mark of corrosion resistance. Failure to remember it may result in the specification of a painted steel enclosure in a corrosive environment, which will fail prematurely.

- Ignoring Internal Conditions. Do not overlook internal condensation. Even a NEMA 4 box with a perfect seal can have water issues inside, especially in an outdoor enclosure that is subject to temperature changes. You might require vents, drains, or heaters to control this.

Conclusion

The choice between NEMA and IP standards is not a preference issue but a precision issue. It requires a good knowledge of your market, a strict analysis of your environment, and the realization that protection is an entire system. When you go beyond a mere comparison of numbers and instead concentrate on the actual environmental challenges that your equipment will encounter, you can be assured of choosing the standard that will provide real, long-term reliability. This systematic process will turn a bewildering decision into a rational one, so that your assets will be safe and functional, no matter what conditions they are exposed to.

FAQS

Q: Can I use a product with only an IP rating in the United States?

A: Yes, you can. There is no law preventing it. However, many industries and customers in North America are accustomed to the NEMA system and may require a NEMA Type rating for compliance with their project specifications. It is always best to clarify customer requirements.

Q: Is a product with both a NEMA and IP rating better?

A: A dual-rated product is not inherently “better,” but it is more versatile. It demonstrates that the manufacturer has certified the product for both the North American and global markets, which can be a sign of quality and provides greater flexibility for global distribution.

Q: What does the “P” in NEMA 6P mean?

A: The “P” stands for prolonged. A NEMA 6 rating is for temporary submersion, while a NEMA 6P rating indicates the enclosure can withstand prolonged submersion under conditions defined by the manufacturer. It is the most robust submersible rating in the NEMA system, roughly equivalent to a specific type of IP68.

Q: If an IP rating has an ‘X’ (e.g., IPX6), what does that mean?

A: The ‘X’ is used as a placeholder when a rating for one of the two categories (solids or liquids) is not provided or not required. For example, IPX6 means there is no specified rating for solid ingress, but the enclosure is protected against powerful water jets.