Introduction

Within the enormous vocabulary of mechanical engineering, some parts, through their omnipresence and essential usefulness, are nearly invisible. A good example is the piano hinge. Its name brings to mind the beautiful piano lid of a concert grand, protecting the delicate soundboard within, but its use is much more widespread than the concert hall; it is used as a structural component in such diverse industries as aerospace and custom cabinetry. Among the many types of hinges, it is a straightforward, strong answer to a complicated question: how to give a continuous, evenly distributed support over the whole length of a joint.

This guide is supposed to be a comprehensive one, breaking down the piano hinge to its fundamental principles, to its practical selection and use.

What Is a Piano Hinge

A piano hinge (more formally, a continuous hinge, in engineering terms) is a long, thin hinge that extends the entire length of the door, panel, or box to which it is attached. In contrast to smaller hinges likeconventional butt hinges, which offer support at two or three discrete locations, the piano hinge spreads the load stress of the load over the entire seam. This constant design reduces the stress on any one point of the material, which makes the assembly much stronger and durable.

How Does a Piano Hinge Work

Piano hinge mechanics are a lesson in beautiful simplicity. It is composed of two long, flat leaves, and a series of interlocking knuckles to make a central tube. These knuckles have a metal central pin that runs through the center of them, making one continuous pivot point. It is, in a way, the mechanical backbone of the two interconnected objects.

When force is exerted, say on opening a heavy lid, the force is not concentrated on a few screws and a small area of the frame. Rather, it is spread out along the whole length of the hinge, through all the knuckles and all the fasteners. This distribution eliminates the warping, sagging, and ultimate collapse that can bedevil assemblies that depend on spaced hinges, particularly in the case of long, heavy, or frequently used panels. The outcome is a smooth operation with stable and very durable rotational movement.

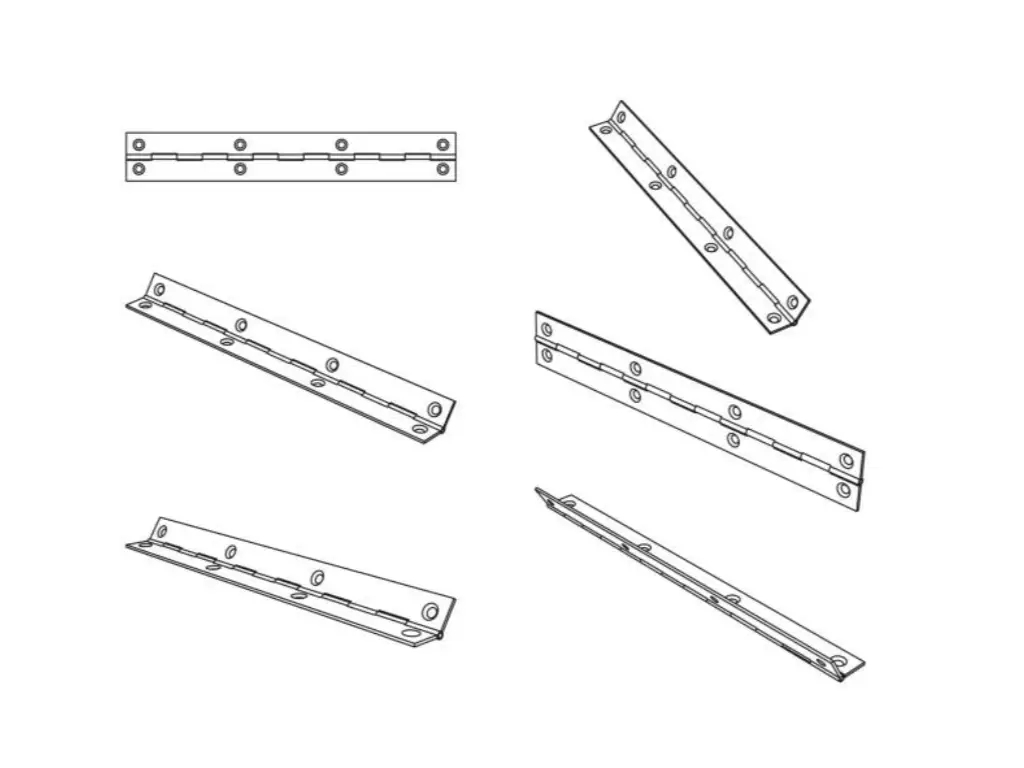

Types of Piano Hinges: Choosing the Right One for Your Project

The correct knowledge of the piano hinge starts with a survey of the main types of continuous hinges. The three main pillars that determine the nature and appropriateness of a hinge are the material composition, the intended application and the installation characteristics. To make the right choice, one has to be acquainted with this taxonomy.

By Material

The material from which a hinge is forged is the primary determinant of its strength, weight, corrosion resistance, and lifespan.

| Property | Stainless Steel | Carbon Steel | Aluminum Alloy | Brass |

| Cost | $$$$ | $ | $$ | $$$$ |

| Weight | 5-7 kg/m² | 7-9 kg/m² | 2-4 kg/m² | 5-7 kg/m² |

| Load-Bearing Capacity | 1500-2000 N (Very High) | 2000-2500 N (Highest) | 800-1200 N (Medium to High) | 1000-1500 N (Medium) |

| Corrosion Resistance | 1000+ hours with no significant corrosion (Excellent) | Begins to corrode within 48 hours (Requires protective coating) | Good corrosion resistance, 300+ hours | 300-500 hours with minor corrosion (Good) |

| Best Use Environment | Marine, Outdoor, Food Service, Corrosive Environments | Indoor, Dry, Heavy-Duty Structural | Aerospace, Transportation, Lightweight Environments | Decorative, Fine Furniture, Architectural |

Note: The data on load-bearing capacity and corrosion resistance is based on typical material properties. Actual performance may vary depending on alloy composition, processing, and environmental conditions.

Stainless Steel Piano Hinges

Stainless steel is an alloy of iron with a large proportion of chromium that forms a passive, self-healing film of chromium oxide on the surface. This coating gives the material its trademark rust and corrosion resistance. Hinges are commonly graded in two grades:

- Type 304: This is the most common grade with good corrosion resistance in most environments. It is the benchmark of quality commercial, medical and food-service equipment.

- Type 316: This grade has molybdenum added to it, giving it excellent resistance to chlorides and other industrial chemicals. It is the preferred material in marine, coastal installations and laboratory equipment where exposure to harsh substances is inevitable.

Brass Piano Hinges

Brass is an alloy of copper and zinc and is appreciated because of its mix of corrosion resistance and beauty. It is a popular choice in decorative work, fine furniture and architecture where the look is all-important, because of its warm, golden color. Although not as strong as steel, solid brass is very durable and will not rust, gaining a fine patina with age unless polished.

Aluminum Piano Hinges

Aluminum is valued because of its high strength to weight ratio. It is much lighter than steel and thus it is used in aerospace, transportation, and where overall weight is a design limitation. Aluminum has good corrosion resistance due to the naturally formed protective oxide layer, which can be improved by anodizing.

Steel Piano Hinges

The workhorse of the hinge world is standard steel (usually carbon steel). It provides immense strength and stiffness at a cheaper price than stainless steel. Its main weakness is that it is prone to rust. To overcome this, steel hinges are nearly always given a protective coating, usually zinc, nickel, or a paint coating. They are most appropriate in dry and indoor places where they will not be exposed to moisture.

Use-Based

Beyond material, hinges are often categorized by the intensity of the application they are designed to withstand.

Standard Piano Hinges

Most commercial and residential applications are covered by standard-duty piano hinges. They can be used in cabinet doors, toolbox lids, folding tables and access panels that do not support extraordinary weight or extreme operational stress. They provide an ideal combination of performance and economy in normal applications.

Heavy-Duty Piano Hinges

Heavy-duty piano hinges are designed to work in high stress, high load applications. They are made of heavier gauge material, have a larger pin diameter, and in many cases have stronger knuckles. This added weight and power make them essential to large industrial doors, electrical enclosures, security gates, freight-hauling equipment and any application with heavy loadswhere failure is not an option.

With or Without Holes

The final primary classification relates to the method of installation.

Pre-Drilled Piano Hinges

These hinges are provided with holes to take screws drilled at intervals along the leaves. This greatly reduces the time of installation, since no manual measuring and drilling of holes is required. It provides a reliable, precise fastener positioning and is the most common method of fastening used in most general woodworking and assembly applications.

Non-Pre-Drilled Piano Hinges

Also called blank hinges, they lack holes. This gives the installer the greatest flexibility. They are used where a special hole pattern is needed or where the hinge is to be welded, riveted or bonded in place instead of screwed. This is typical of special metal fabrication and industrial manufacturing.

The Common Applications of Piano Hinges

The versatility of the piano hinge has led to its use in many different applications across an extremely wide range of applications in industries. The uses to which it is applied are a testament to its basic utility, offering custom solutions to environments as diverse as the highly demanding to the aesthetically refined.

Material integrity is critical in high-stakes settings. In the aerospace industry, lightweight aluminum piano hinges are essential in cargo doors, access panels and interior parts where strength-to-weight ratio is a key design factor. In the same way, in marine applications, Type 316 stainless steel hinges are essential in hatches, doors, and cabinets that have to endure the unending attack of salt water and corrosive sea air.

The demands of commerce and manufacturing rely on sheer durability. Heavy-duty steel and stainless steel hinges are the norm in the industrial sector in large electrical enclosures, machine guarding, and heavy-duty tool chests to withstand punishing service. This strength is also applicable in commercial architecture where they offer uncompromising support to tall utility doors, service panels, and high traffic cabinetry that are meant to last years of continuous use.

Lastly, in the world of craftsmanship, the hinge is form and function. They provide a beautiful and functional solution to blanket chests, fold-down desks, and any long cabinet door that needs constant support to keep it perfectly straight and not sagging with time. Want to know more about industrial hinges? Visit our complete guide here: https://www.kunlonghardware.com/industrial-hinges-guide/.

How to Select the Right Piano Hinge: A Step-by-Step Guide

Having a clear understanding of the existing types and their typical applications, the next step is to move to the actual decision-making. The choice of the right hinge is a systematic procedure of matching the characteristics of the component with the requirements of the project.

Step 1: Determine the Application Grade & Load Requirements

The first step is to measure the requirements of your application. How much does the door or panel that the hinge has to support weigh and how big is it? The requirements of a lightweight cabinet door in a residential kitchen are orders of magnitude different than a 200 pound steel door on an industrial machine. A standard-duty hinge is adequate when it comes to light to moderate loads. In the case of heavy panels, high-frequency use, or any other case where security and durability are the main concerns, there is no other responsible option but a heavy-duty hinge. Specifying the hinge grade too low is a sure way to early failure.

Step 2: Assess the Material and Finish Needs

Where is the hinge going to work? The material required depends on the answer to this question.

- Dry Environment Indoors: Standard steel with a protective finish is the best combination of strength and value.

- Inside, Potential Moisture: Aluminum or Type 304 stainless steel are very good choices.

- Outside, Rain/Humidity: The minimum requirement is Type 304 stainless steel.

- Marine or Corrosive Chemical Exposure: Type 316 stainless steel is a must.

- Decorative/Architectural: Solid brass or stainless steel with a special finish (e.g., polished, satin) is to be considered.

Step 3: Calculate the Required Dimensions

The dimensions of the hinge are important in order to work and support.

- Length: The hinge is preferable to be as long as the panel it is supporting to get the maximum advantage.

- Open Width: This is the width of the hinge when it is laid flat. It should be broad enough to fit well on the door and the frame without any interference.

- Thickness (Gauge): The leaves thickness is one of the main factors that contribute to the strength of the hinge. Heavier loads need thicker gauges. Check manufacturer specifications, which may give load ratings in terms of hinge length and gauge.

Step 4: Consider the Installation Method and Environmental Factors

The type of hinge you will require (pre-drilled or non-pre-drilled) will depend on your fabrication and assembly process. Pre-drilled holes are perfect when it comes to most woodworking and simple assembly. A blank hinge is required when metalworking is involved where welding is required or a special pattern of fasteners is needed to match internal structures. Re-check your environmental analysis in Step 2, because this last step will make sure that your material selection is sustainable enough to withstand the long-term realities of the application.

Beyond Standard Parts: Why Partner with a Specialist for Your Application?

For engineers, designers, and manufacturers working on high-performance or mission-critical projects, the limitations of off-the-shelf components often become apparent. Standard hinges are designed for common denominators, but specialized applications require engineered solutions.

This is precisely where a specialist partner like KUNLONG makes the critical difference, our hinges move beyond standard components, offering a suite of engineering and quality assurances tailored to your project’s specific needs:

- Engineering Expertise & End-to-End Customization: Leverage our team of 30 engineers, averaging a decade of experience, to receive a 3D concept model for your unique application within 7 days. We provide comprehensive, end-to-end customization covering every detail—from initial function, appearance, dimensions, and materials to the final surface finish etc., all backed by our track record of successfully engineering over 700 unique solutions.

- Uncompromising Quality & Precision: Ensure product longevity with a guaranteed 20,000+ cycle lifespan, validated by 15 rigorous quality checks from raw material to final product. We achieve absolute consistency with a manufacturing precision tolerance controlled down to 0.0005mm.

- Certified Materials & Supply Chain Integrity: Build with confidence using fully traceable, RoHS-certified materials, with every batch backed by its SGS inspection report for full verification. Our commitment to a stable supply chain and full material traceability ensures reliability and compliance for even the most demanding industries.

Best Practices for Installing and Caring for Piano Hinges

The installation is very important in order to get the maximum out of a piano hinge.

- Preparation: Both the door and the frame must have flat, flush and clean mounting surfaces. Any discrepancies will be converted to an unaligned hinge.

- Alignment: Place the hinge in position along the edge of the door or panel. To achieve a clean, inset appearance, you might have to route a shallow groove (a mortise) into which the hinge leaves can rest. Temporarily clamp or tape the hinge in position to make sure it is straight before driving any fasteners.

- Fastening: Drill pilot holes for your screws to avoid splitting the wood. Begin by screwing screws into the holes at the very top and bottom of the hinge. Before installing the rest of the screws, check the alignment of the door and its swing.

It is easy to take care of your hinges. Clean them off dust and debris periodically. Indoor hinges will run smoothly with a drop of light machine oil or silicone spray on the pin once a year. A marine grade grease can be used on outdoor or heavy-duty hinges. Always ensure that fasteners are tight especially in high vibration areas.

Conclusion

The piano hinge is a testament to good engineering principles in its elegant and continuous form. It is an element whose worth is much more than its price, offering a degree of strength, stability and durability that discrete hinges cannot offer. Selection is not a game of chance but a conscious and rational process of fitting the proper material, grade and dimension to the requirements of a particular application. A well-selected and fitted piano hinge is an investment in structural integrity and perfect performance, whether it is a straightforward home project or a complicated industrial assembly.