Introduction

A hinge choice is one of the most fundamental design and engineering choices, but it is frequently treated as an afterthought. This is a serious omission. A hinge is not just a part that enables a door or panel to open and close, but the complete mechanism that controls the movement of the object, supports its weight, and keeps it in the correct position throughout its life. A hinge that is not specified correctly may result in functional failure, premature wear and an unacceptable user experience.

This guide is a systematic and comprehensive review of hinge types, materials and selection criteria, enabling you to make an informed and technically sound selection of any application.

What Are Hinges? Function and Structure

In essence, a hinge is a mechanical bearing that joins two items. It is mainly used to enable a small angle of rotation between them. Although designs are extremely diverse, most traditional hinges consist of three basic components. These components are critical to the understanding of functional differences between types of hinges.

Leaf

The leaves are the plates of the hinge that are affixed to the connected objects. They are the surfaces that support the load and transmit it to the remainder of the assembly. Leaves are usually made of metal, and have holes, or perforations, pre-drilled to receive mounting fasteners like screws or bolts. The load-bearing capacity of a hinge is largely determined by the size, shape and thickness of the leaves.

Knuckle

The knuckle is the hollow, round, interlocked part of the hinge in which the pin moves. It is the pivot point. The knuckles of the two leaves are made to meet in one continuous barrel. The strength of this hinge and its ability to resist wear and shear forces are dependent on the length, diameter and integrity of this barrel. The more knuckles there are, the better the load is usually distributed, and the smoother the action and the longer the service life is.

Pin

The rod that fits into the knuckle is the pin that holds the two leaves together and acts as the rotating axis. Pins may be either fixed, i.e., permanently part of the hinge assembly, or removable, in which case the two objects can be easily separated without uninstalling the hinge leaves. The pin material and diameter are important to the overall strength and security of the hinge.

Common Types of Hinges and Their Best Uses

Hinges are best understood through their intended application. They are broadly categorized into standard designs, which serve common structural purposes, and specialty designs, which are engineered to solve specific functional challenges.

Standard Hinges

These hinges represent the most prevalent designs used in general construction and manufacturing.

Butt Hinge

A butt hinge consists of two rectangular leaves of the same size with a pinned or fixed knuckle. It is made in such a way that when the hinge is in the closed position, the leaves are flush against one another. This design, which is the most common type of hinge, usually needs a recess, or mortise, to be cut into the mounting surfaces so that the hinge is flush with the surface.

- Best For: Residential doors, commercial doors, cabinets, general-purpose chests, and enclosures. This type of butt hinge is a versatile solution.

- Pros: Strong, durable, and widely available. Capable of supporting significant weight when sized correctly.

- Cons: Requires precise mortising for a flush installation, which increases labor and complexity.

Piano Hinge

The piano hinge is also called a continuous hinge and it extends the entire length of the hinge to connect the two items. It is made of two long leaves with a knuckle running the length of the leaf, giving very even support along the seam.

- Best For: Large chest lids, fold-down workbenches, toolboxes, industrial enclosures, and aircraft panels where load distribution and alignment are critical. It’s also ideal for piano lids and storage boxes.

- Pros: Provides excellent strength and even load distribution, prevents warping, and maintains precise alignment along a long edge.

- Cons: Can be difficult to install due to its length and the large number of fasteners required. The long knuckle can be a potential pinch point.

Flush Hinge

The flush hinge is a modification of the butt hinge to be used in light-duty applications. One of the leaves is a little smaller and is made to fit into the other when closed, so that there is no mortise. The whole hinge is placed on the surface of the material.

- Best For: Lightweight cabinet doors, small boxes, and applications where mortising is impractical or undesirable.

- Pros: Simple and fast to install, as no recess is required.

- Cons: Not suitable for heavy loads. Less strong and secure compared to a butt hinge.

T-Hinge

The T-hinge is a combination of a rectangular butt-style leaf to mount on a narrow frame or post with a long, triangular or rectangular strap leaf to mount on a wider door or gate. The design offers wide support to avoid sagging.

- Best For: Shed doors, barn doors, large garden gates, and other rustic or heavy-duty outdoor applications. This includes warehouse gates and patio doors.

- Pros: Excellent for supporting wide, heavier doorsby distributing the weight over a larger surface area.

- Cons: A highly visible design may not be suitable for all aesthetics. Offers less security than a butt hinge against forced removal.

Ball Bearing Hinge

It is a high-performance version of the butt hinge. It uses tiny ball bearings between the knuckles of the hinge. These bearings substitute the sliding friction with the rolling friction, which makes the action much smoother and easier.

- Best For: Heavy-duty entry doors, high-traffic commercial doors, and any application requiring smooth, quiet operation and long-term durability. It offers extra strength for frequent use.

- Pros: Extremely smooth and quiet operation. Highly durable and capable of handling heavy loads with minimal wear.

- Cons: More expensive than standard butt hinges.

Specialty Hinges

These hinges are engineered to fulfill specific functional requirements, such as concealment, position control, or unique rotational movement.

Concealed Hinge

This design is commonly known as a European hinge and is designed to be completely invisible from the outside when the door is closed. It is made up of a hinge body which is mounted within a circular mortise in the door and a mounting plate which is attached to the cabinet wall.

- Best For: Modern frameless kitchen cabinets, high-end furniture, and any application requiring a clean, seamless exterior aesthetic. This includes full overlay and half overlay cabinet designs.

- Pros: Completely invisible for a minimalist look. Most models offer three-way adjustability (height, depth, side-to-side) for perfect door alignment.

- Cons: Installation is complex, requiring a specific large-diameter hole to be drilled for the hinge cup.

Torque Hinges

These hinges are also referred to as friction hinges or position control hinges and are made in such a way that they offer resistance to movement through an internal mechanism. This enables a door or panel to be held open at any angle without the use of a secondary support such as a gas strut or lid stay.

- Best For: Laptop screens, medical equipment panels, industrial control boxes, equipment access panels, and any lid that needs to be held open securely.

- Pros: Enables precise position control and hands-free operation. It can simplify a design by eliminating the need for additional support components.

- Cons: Higher cost. The amount of torque is pre-set and must be carefully matched to the weight and size of the panel.

Detachable Hinges

Detachable hinges, also known as lift-off hinges, are made in two distinct parts (a male leaf with a fixed pin and a female leaf with a hollow knuckle) that are easily separated. This enables a door or panel to be removed easily and quickly without tools. These include types of flag hinges and rising butt hinges.

- Best For: Removable equipment covers, enclosure doors requiring frequent access for maintenance, and temporary installations.

- Pros: Allows for extremely fast and simple removal and re-installation of a door or panel.

- Cons: Offers lower security than non-detachable hinges. Must be specified as right-hand or left-hand.

Offset Hinge

Offset hinges have leaves that are made to move the pivot point off the cabinet or door frame when open. This movement moves the door fully out of the way of opening, giving maximum clearance.

- Best For: Hospital doors, accessibility doors for wheelchair access, and tight spaces where a full, unobstructed opening is required.

- Pros: Maximizes the clear width of an opening. It can help clear thick trim or molding.

- Cons: Can be more complex to install correctly. The offset dimension must be carefully chosen.

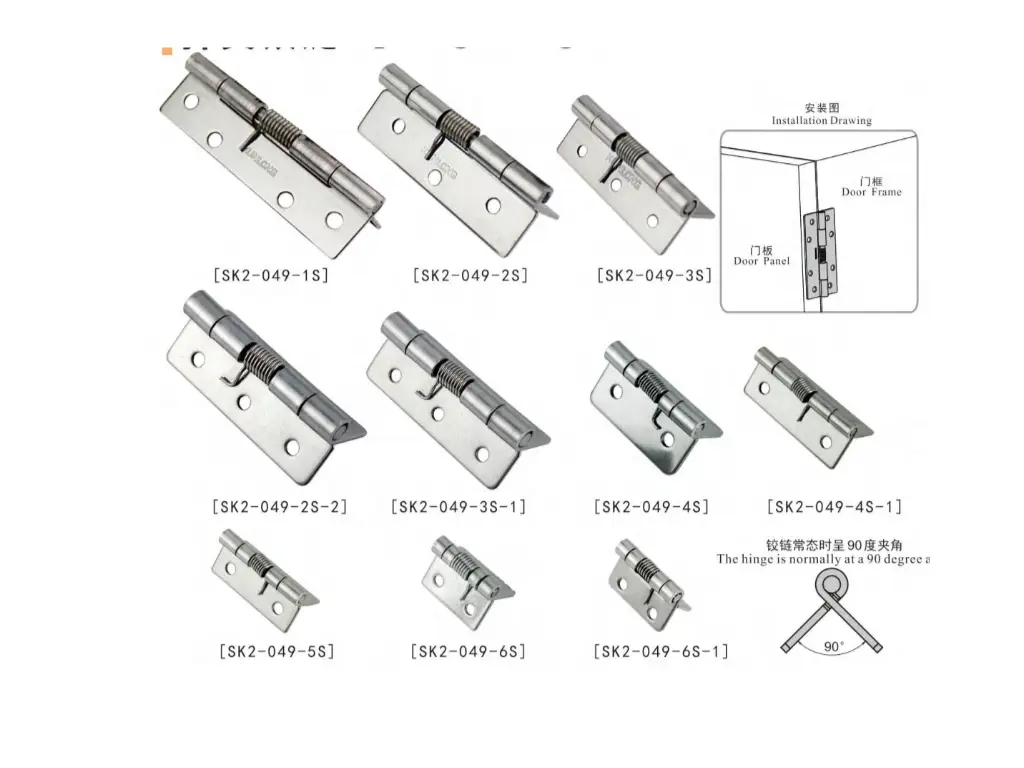

Spring-Loaded Hinge

Such hinges have a spring mechanism that automatically closes or opens a door. They may be single-action (closing the door in one direction) or double-action (permitting the door to swing in both directions and swing back to center).

- Best For: Screen doors, fire doors (self-closing), gates, and saloon-style swinging doors (double-action).

- Pros: Provides automatic closing or opening for convenience and safety. Tension is often adjustable.

- Cons: The constant spring tension can cause faster wear. The closing action can be forceful if not adjusted properly.

Barrel Hinge

A barrel hinge is a small specialized hinge consisting of two barrel-shaped pieces mortised into holes drilled into the edges of the two connecting pieces. The hinge is nearly invisible when closed.

- Best For: Fine woodworking, jewelry boxes, small cabinet doors, and any project where a discreet, strong hinge is needed.

- Pros: Nearly invisible when installed, providing a very clean look. Strong for their size.

- Cons: Requires precise drilling for installation. Not suitable for high-load applications.

Pivot Hinge

A pivot hinge is fitted on the top and bottom of a door, so that the door swings on one point at the top and bottom corners instead of swinging on the side of the door on the door jamb.

- Best For: Heavy or oversized modern architectural doors, glass doors, and applications where a traditional side-mounted hinge is not feasible or desired.

- Pros:Can support extremely heavy doors. Creates a unique, clean aesthetic with minimal visible hardware.

- Cons: More complex installation than standard hinges. Reduces the clear opening width slightly as the pivot point is inset from the frame.

Beyond Type: Choosing the Material and Finish

The performance and longevity of a hinge are as dependent on its material composition and surface treatment as on its mechanical design.

Materials Comparison

- Steel: Hinges are most often made of steel because it is strong and cheap. Standard carbon steel is tough and prone to corrosion unless treated.

- Stainless Steel: A steel alloyed with chromium, and usually nickel (e.g., Grades 304, 316). It has superior corrosion resistance and is therefore vital in outdoor, marine and sterile applications. Grade 316 is better resistant to chlorides and is the marine standard.

- Brass: A mixture of copper and zinc, which is a good corrosion resistant and aesthetic material. It is less hard than steel and is commonly used as decorative and residential hardware.

- Aluminum: It is a lightweight material that is naturally corrosion resistant. It is not as robust as steel but is perfect in places where weight is a major factor like in aviation and automobile applications.

- Bronze: Bronze is a mixture of copper and tin and it is very durable and highly resistant to corrosion especially in the marine environment.

Surface Finishes

Surface finishes are used to protect the underlying material and to give a desired appearance.

- Plating: The surface is electroplated with a thin layer of another metal (zinc, chrome, nickel, etc.). Steel is commonly and cheaply corrosion-inhibited by zinc plating. Chrome offers a reflective, hard and durable surface.

- Powder Coating: A dry powder is sprayed on using electrostatic and baked in heat to create a hard finish that is more durable than regular paint. It has good corrosion and abrasion resistance and is offered in a variety of colors.

- Anodizing: An electrochemical treatment applied to aluminum that thickens the natural oxide layer, enhancing corrosion resistance and surface hardness. It may also be used to provide color.

- Polished/Brushed: These are mechanical finishes. Polishing gives a mirror finish and brushing a fine, unidirectional satin finish. These are usually used on stainless steel or brass.

How to Choose the Right Type of Hinge for Your Project

Selecting the correct hinge requires a systematic evaluation of the project’s specific demands. The following factors must be considered in concert to arrive at the optimal solution.

Load and Weight Support

The first is to find the weight of the door or panel. This will dictate the size, material and amount of hinges needed. Hinge manufacturers give load ratings on their hinges. The important thing is to use enough hinges to take this weight without straining any one of them. On heavy doors, never use a light-duty or ball-bearing hinge.

Material Compatibility

The hinge material must match the door and frame material and the surrounding environment. Galvanic corrosion or premature failure may occur when an inappropriate material is used.

Motion Needs

Take into account the range of motion that is needed. Does the door have to open 90, 180 or 270 degrees? Does it have to be self-closing, soft-closing or remain in a fixed position? The responses to these questions will guide you to spring-loaded, concealed, or torque hinges.

Aesthetic

Decide whether the hinge is to be a visible design feature or totally concealed. Concealed, pivot, and barrel hinges provide an invisible appearance, whereas T-hinges and decorative butt hinges are supposed to be visible. The finish must match other hardware and the general design scheme.

Installation Environment

The material and finish are determined by the environment. High corrosion resistance is required in outdoor and marine applications. Medical settings or clean rooms need easy-to-sterilize materials. The hinge and fastener will also be dependent on the substrate material (wood, metal, composite).

To give a better idea of how these factors combine for different typical applications, the following table offers more detailed recommendations for hinge types based on project requirements:

| Project Type | Key Considerations | Visibility | Recommended Hinge(s) | Load Capacity | Special Features |

| Kitchen Cabinet | Seamless look, adjustability | Invisible | Concealed (Euro) Hinge | Low-Medium | Soft-Close, Self-Close |

| Heavy Entry Door | High frequency, security, weather | Visible | Ball Bearing Hinge | High | Durability, Smooth Action |

| Industrial Enclosure | Secure access, durability | Variable | Piano Hinge, Torque Hinge | Medium-High | Position Control, Even Support |

| Lightweight Box | Simplicity, low cost | Visible | Flush Hinge, Barrel Hinge | Low | Easy Installation |

| Outdoor Gate | Weather resistance, sag prevention | Visible | T-Hinge, Stainless Strap Hinge | High | Corrosion Resistance |

| Architectural Panel | Hidden mechanism, precision | Invisible | Pivot Hinge | Variable | Minimalist Aesthetic |

Why Choose KUNLONG for Your Hinge Needs

KUNLONG is the hinge partner of choice in industries where precision, strength, and long-term reliability are not negotiable. We do more than provide hardware; we provide engineered solutions that are specific to your requirements. We offer a range of sizes to fit any project.

What Sets KUNLONG Apart:

- Unmatched Quality Control: Each hinge goes through 15 major checks between raw material and finished product and is 100 percent quality assured. Tolerances are regulated to 0.0005mm.

- Certified Materials: All raw materials are certified, with SGS and ROHS reports available to guarantee strength, safety, and compliance.

- Custom Engineering Solutions: With 30 in-house engineers averaging 10+ years of experience, we’ve delivered over 700 custom hinge functions. Standard custom sketches can be delivered in as little as 7 days.

- Expert Technical Support: Our team responds to customer feedback within 12 hours and provides tailored guidance to ensure the perfect fit for your application.

- Full-Scale Manufacturing: With 180 advanced machines and certifications including ISO, CE, CQC, and ROHS, we’re equipped to deliver excellence at scale.

Choosing KUNLONG means investing in high-performance hinges that protect the integrity of your final product—for life. Explore our range of industrial hinges or contact our engineering team to discuss your project.

Pro Tips for Hinge Installation and Adjustment

Correct installation is paramount to hinge performance.

Essential Tools

Accurate tools are needed in a professional installation. The most important are a sharp chisel and mallet (mortising), a combination square to lay out accurately, a marking gauge or knife to score the outline, a power drill with properly sized bits to drill pilot holes, and a screwdriver to finish fastening.

How to Mortise

Mortising provides a recess to fit the hinge leaf so that it lies flush with the surface.

- Position and Mark: Put the hinge leaf in its final position and trace its outline with a sharp marking knife.

- Set Depth: Mark the depth of the mortise on the edge of the door or frame with a combination square or marking gauge, the same thickness as the hinge leaf.

- Cut the Perimeter: Cut along the marked outline to the prescribed depth using a sharp chisel and mallet.

- Remove Waste: Cut a set of parallel relief cuts in the mortise region. Next, by holding the chisel bevel-down, pare off the waste with care, so as to form a smooth, even recess.

Troubleshooting Tips

- Squeaking: This is usually due to friction and dirt in the knuckle. Wipe the hinge and use appropriate lubricant such as lithium grease or silicone-based spray.

- Sagging Door: This is normally caused by loose or stripped screws in the top hinge. See whether you can tighten the screws. When the holes are stripped, a longer screw can be used to grab new wood or the hole can be filled with a wooden dowel and glue then re-drilled.

- Door Binding: When a door sticks to the frame, the mortises are probably too deep. Shim the hinge by putting a thin piece of cardboard behind the leaf to push it out a little.

Conclusion

The hinge is a basic part the significance of which is directly related to the outcomes of its malfunction. Proper specification is based on a thorough knowledge of its structure, types and materials. You can go beyond a guess and make an engineering-based decision by systematically analyzing the needs of your project, including load and motion, environment and aesthetics. Choosing the right hinge is an investment in functionality, safety and long-term performance, and the end result is a final assembly that will work precisely as it was intended to, time after time.

FAQS

Q: What is the most commonly used hinge?

A: The butt hinge is, without question, the most commonly used hinge. Its simple, strong, and versatile design makes it the standard for millions of industrial enclosures, residential and commercial doors worldwide. For modern cabinetry, the concealed hinge has become the dominant standard.

Q: How many different hinges are there?

A: There is no definitive number, but there are hundreds of distinct hinge designs. While this guide covers the most common and important categories, there are countless variations and highly specialized hinges engineered for specific industrial, aerospace, marine, and electronic applications, each with unique properties and functions.

Q: What is a hinge that folds back on itself?

A: A hinge that allows a door or panel to fold completely back 180 degrees to lie flat against the adjacent surface is typically a double-action hinge or a specific type of offset or swing-clear hinge designed for a full range of motion.